Blog

These days, the world’s cities are filled with high-rise apartment buildings and soaring office spaces that require elevators to travel faster than ever before. Many of these buildings – especially older ones – may still use elevators powered by some type of geared traction machine, but this technology is now widely considered cost-prohibitive and outdated.

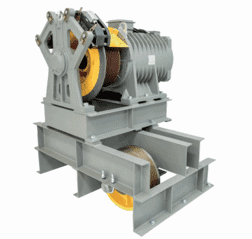

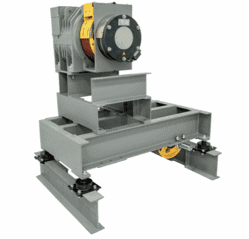

Gearless machines have gradually replaced geared systems over the past several decades, largely because of their low maintenance requirements and long service life. Recent advances in gearless technology have made them an even more valuable investment. While traditional gearless DC motors usually require an equipment room and take up a lot of space, the rise of machine-room-less (MRL) elevator systems has made smaller AC gearless machines a popular choice in buildings under 20 stories in recent years and even being used as basement machines. Gearless motors offer significant benefits over their geared counterparts, including:

1. Lower Maintenance Costs

Many buildings already have a geared system in place, and decision-makers may not be inclined to replace an aging system as long as it still works. However, geared elevator machines generate a lot of friction and heat, which ultimately leads to significant wear and tear. As crown gear or worm gear wears down, these parts must be replaced to ensure that the elevator continues to run properly.

Standard and Custom Gearless Packages from 2,500 lbs. to 8,000 lbs. Capacity

As a result, most geared systems require more frequent maintenance and inspections to ensure that they continue to function. Gearless systems, on the other hand, don’t suffer the same level of wear and tear that geared systems do, and require only occasional inspections of ropes and sheaves.

A DC gearless motor can last between 30 and 70 years, and this lifespan can often be extended beyond a century with basic maintenance. Modern AC gearless MRL systems can last up to 20 years before requiring refurbishment or replacement, and their smaller size and space requirements make them simpler to replace than larger, more complicated geared assemblies.

In addition to these benefits, gearless motors don’t have the same lubrication requirements as geared motors, which means there’s no need for oil changes and no risk of hydraulic or other fluid leaks.

2. Operational Efficiency

Modern gearless machines offer significant cost savings over geared systems or older gearless equipment. Gearless systems are a particularly popular choice for use in buildings with a Leadership in Energy & Environmental Design (LEED) certification because of the significant energy savings they provide. Tax credits for energy efficiency can also help offset the general day-to-day costs of elevator operation.

Gearless machines are highly energy efficient, especially when equipped with the latest in gearless AC or DC drive technology. For example, a regenerative drive recycles energy back into the grid, which can further lower energy costs for a building.

In addition to reduced energy consumption, gearless traction elevators move at speeds of up to 2,000 feet per minute. This is significantly faster than geared models, enabling passengers to travel throughout your building much more efficiently.

3. Quieter Operation

The tight tolerances required by geared traction systems sometimes cause undue grinding or other sounds which make passengers uncomfortable. As passengers report these sounds, building managers must investigate, which can raise maintenance costs. Without gears, gearless motors in elevator systems offer a quieter and more comfortable ride for passengers.

These three reasons make it clear that transitioning from geared to gearless machines will help you optimize efficiency, increase performance, and reduce operating costs for your business.

Renown Electric Motors and Repair has helped companies in every industry reap the benefits of using the most effective electric motors available today. Backed by a longstanding commitment to excellence and quality customer service, we’re ready to help you plan your transition to gearless machines in your elevator systems. If you’d like to learn more about gearless machines or our other products and services, contact us or give us a call at 877-742-3665.

Comments are closed