Motor Repair Projects: See How Renown’s Process Works

Comments Off on Motor Repair Projects: See How Renown’s Process WorksRenown Electric treats every motor project — big or small — with the same level of care to produce the best quality results for our customers.

To illustrate how we handle motor repair projects smoothly from start to finish, we’ve compiled details from some of our past jobs into a new case studies page on our website. Here are a few highlights:

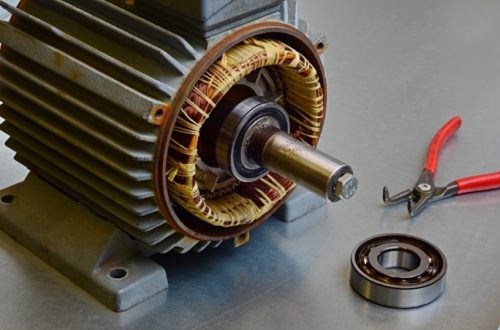

Motor Repair

In one recent case, a silicon rubber mill was experiencing brake issues as the result of an outdated control panel. The owner of the mill, which no longer met the required safety standards, approached Renown for motor drive maintenance assistance to help create a safer work environment. Renown collaborated with Mann Electric and a top motor and machine control support company, Benshaw Advanced Controls and Drives, to examine the controls.

Collaboratively, we determined that the best solution would be to completely replace the control panel, while accommodating the old wound rotor motor. We reestablished workplace safety at the mill by providing a new motor control panel with advanced synchronous control capabilities, a soft start and emergency stop functionality to meet current workplace health and safety standards.

Industrial Motors

In an AC and DC motor case study, Renown conducted a motor bearing current test with our CoolBLUE inductive absorbers and NaLA noise line absorbers to find a solution to harmful voltage spikes, which had been causing fluting and lubrication breakdown. We found that these absorbers, also known as common mode chokes, reduced bearing damage by eliminating these high frequency currents and keeping voltage within safe limits.

In another motor bearing current test — in this case, for elevator motor drives — Renown found that the common mode chokes reduced harmful electrical “noise” by up to 60% in DC motors and 65% in AC motors. This eliminated harmful currents to the armature and bearings and in the long run will reduce maintenance and prolong the life of the motor.

Renown Can Help

For more examples of recent projects and to learn how Renown can help you to prevent motor problems across a variety of applications, please visit our case studies page.