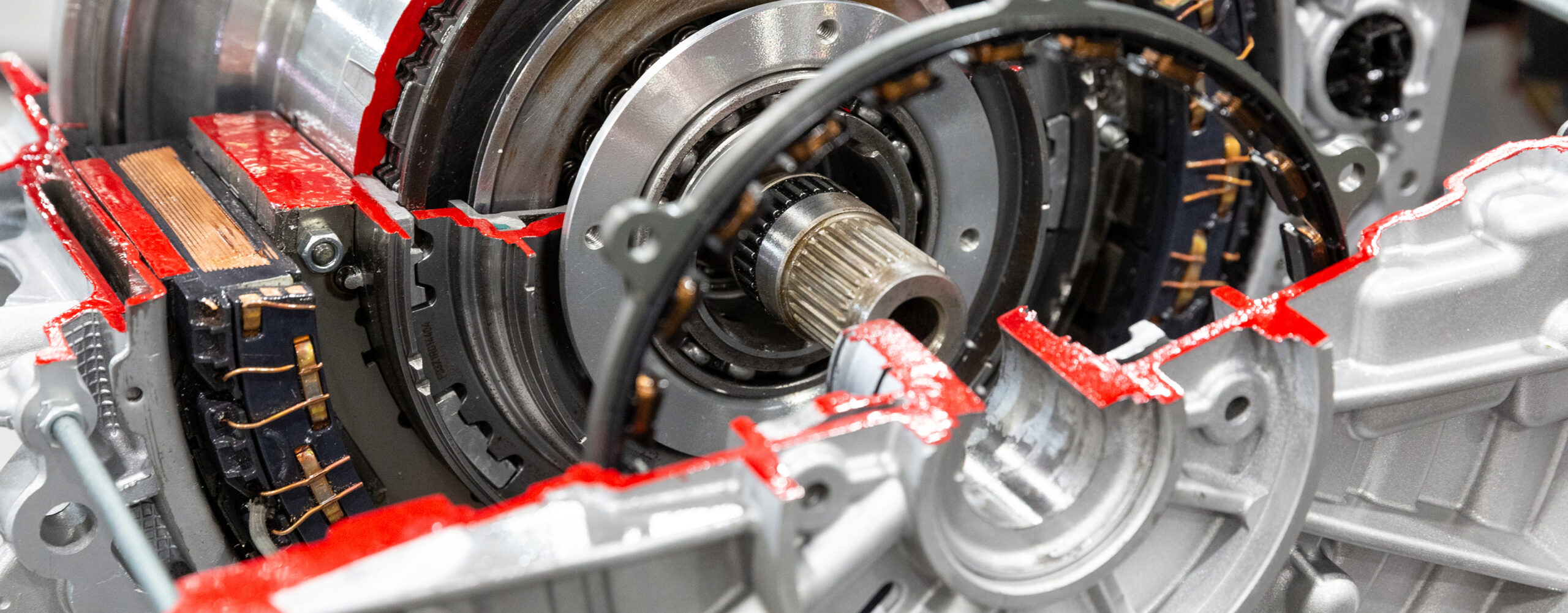

When a rubber mill’s control system started failing, it created a significant safety hazard for employees. The mill’s motor braking system was malfunctioning, which not only hindered production but also failed to meet the required Occupational Safety and Health Administration (OSHA) standards for emergency stops. The outdated control panels were difficult and expensive to repair, but the old motor itself was worth saving because of its high torque output.

Equipment

English Electric 100 HP, 550 VAC, 110 FLA, 40°C, 900 RPM

Objective

The goal was to repair the mill’s control system to ensure employee safety by meeting OSHA’s emergency stop (E-STOP) standards.

Project Duration

2 Weeks

Challenge

The primary challenge was integrating a new control system with an old, high-torque wound rotor motor. The mill’s control panel was non-responsive and outdated, which made it a liability and a safety risk. Simply replacing the old motor was not a viable option because of the specific performance characteristics it offered. The solution needed to be both safe and cost-effective, extending the life of the existing equipment rather than replacing it entirely.

The Solution

Renown teamed up with Benshaw Advanced Controls and Drives, a top motor and machine control support company that works with a variety of OEMs for machine-specific solutions. Benshaw also runs a state-of-the-art manufacturing facility to deliver design and testing services to ensure that equipment meets a wide range of safety and operational standards.

Under Occupational Safety & Health Administration safety standards, mills must stop within specified limits — regardless of size or arrangement — or employees could be exposed to a hazard. To continue operations, the customer needed controls that operated properly and adhered to OSHA standards.

After an examination of the controls, Renown and the customer determined that a motor replacement would not be in the long-term interests of the customer. Instead, they proposed a new control panel and controls that would meet the safety standards while accommodating the old wound rotor motor.

Control Specifics for Rubber Mill Motor

| English Electric 100HP | 550VAC |

| 110 FLA | 40C |

| 900 RPM | P.F. 0.8 Cont. Duty |

| Exciter 125VDC | Field Current 21 |

Benshaw was able to deliver a completely new motor control panel with synchronous soft starter, exciter controls, forward and reversing contactors, and braking contactor. These next-generation solid-state synchronous controls focused on control capabilities for day-to-day performance as well as emergency start and stop operations.

By working with Benshaw Advanced Controls and Drives, Renown Electric was able to generate a next-generation solid-state synchronous control to provide a panel with up-to-date standards and certifications.

The new controls and braking contactor can be used in conjunction with existing braking resistors, allowing the mill to stop in an emergency situation as quickly as safety regulations demand.

Mann Electric’s installation team removed and installed the cabinet and updated controls on the mill. Renown Electric provided application advice leading to an overhaul and rewind on the existing motor. Altogether, teaming up with the customer, we were able to update aging machinery and extend its usable lifetime, creating long-term savings while still delivering quality operations.

Control Panel – Before

Control Panel – After

Process

The project followed a clear, three-phase process.

Assessment and Recommendation: Renown Electric, working with the client, examined the existing controls and determined that a motor replacement was not necessary. Instead, they proposed a new control panel and control system to meet safety standards.

Collaboration and Design: Renown Electric partnered with Benshaw Advanced Controls and Drives to design and manufacture a new, state-of-the-art solid-state synchronous control panel. This new panel was specifically engineered to work with the old motor.

Installation and Overhaul: Mann Electric’s installation team removed the old cabinet and installed the new one. Renown Electric provided the motor overhaul and rewind, ensuring the motor would perform optimally with the new controls.

Get in Touch with our Skilled Team

No matter your industry or application, we’re here for you. Contact us to learn more about our extensive capabilities, and how we serve clients across industries to ensure their motors are operating at their best.