Overview of the Hydroelectric Sector

Hydroelectric energy is one of the largest sources of renewable energy in North America. To generate hydroelectric power, moving water from streams or rivers is directed through dams and hydroelectric power plants. Turbines submerged in the water derive mechanical energy from the motion of the water and convert it into usable electricity through the use of hydroelectric generators.

Hydroelectric generators are exposed to corrosive moisture, extreme temperatures, and high pressure on a regular basis. The extreme conditions common in hydroelectric operations place a great deal of strain on the generator. It is therefore critical to ensure that generators receive timely repairs and maintenance to keep hydroelectric operations running smoothly and reliably.

The Importance of Generator Repairs for the Hydroelectric Sector

When an issue arises with your hydroelectric generator, it is important to complete repairs as soon as possible. Left untreated, problems will grow, leading to costly repairs, downtime, and even safety hazards. When your equipment is maintained and inspected regularly, you can identify potential problems before they happen, thereby reducing the cost of repairs and the risk of damage to other parts of your system.

Common Hydroelectric Generator Repairs

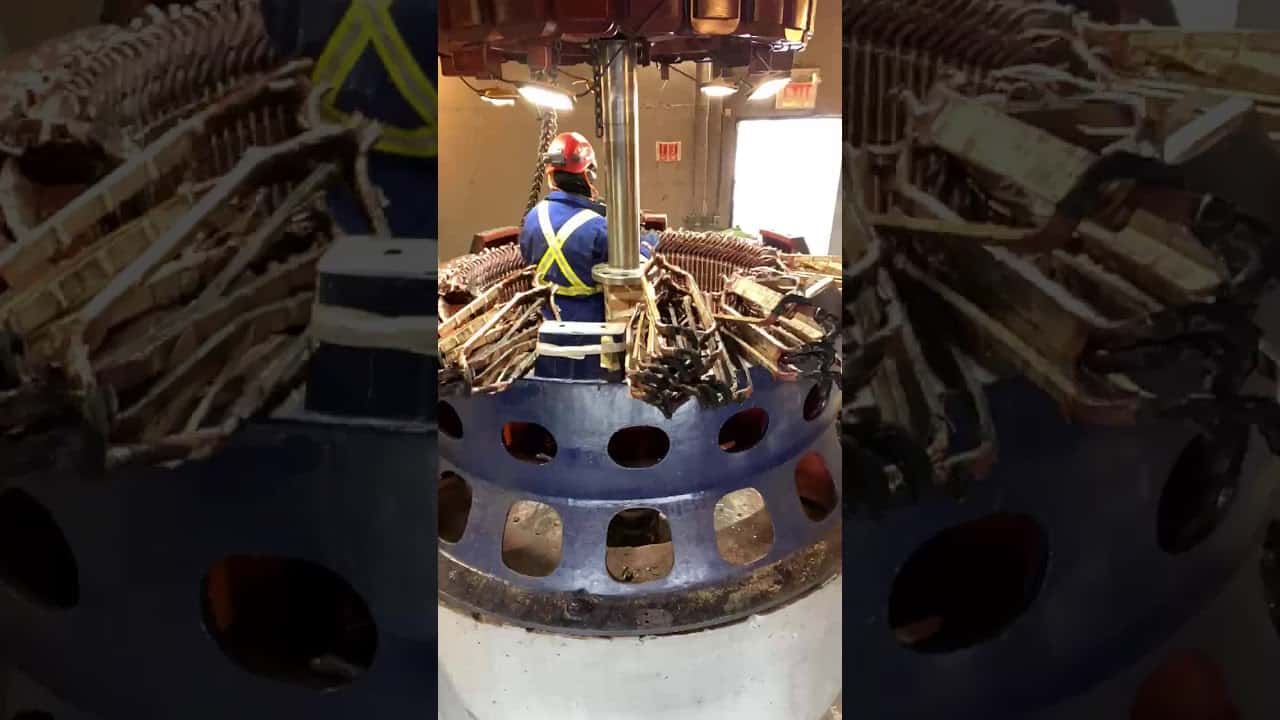

Hydroelectric generator repairs usually fall into two categories: rewinding and mechanical repairs.

Rewinding

With normal operation, the windings in a hydroelectric generator will deteriorate over time due to thermal aging of the insulation system. When rewinding the stator of a hydroelectric generator it is often possible to increase the copper cross sectional area of the conductors. In this case, the copper losses of the windings are reduced and thereby the overall efficiency of the generator is enhanced.

Mechanical Issues

The most common mechanical issues in hydroelectric generators relate to alignment and balance. Loose bearings, broken fasteners, and damaged welds and rotors can all create unwanted vibration and pressure on components within the generator. This increases the wear on components and can significantly decrease their service life. Spectrum and vibration analysis can help to detect unwanted vibration and pinpoint the cause, so you can conduct repairs before they cause damage to other parts of the generator.

Other mechanical repairs that are common in hydroelectric generators include:

- Slip ring, bearing, and flange replacement and repair

- Bush rigging replacement

- Exciter repair

- Hydro Shaft machining

- Flange face recutting and brake ring machining

- Stator and rotor cleaning

Why Work with Renown Electric for Electric Motor and Generator Repair Services?

At Renown Electric, we pride ourselves on serving our customers with the highest degree of professionalism and expertise. Our seasoned technicians will keep your electric motors and generators operating with exceptional efficiency 24/7.

Our capabilities within the hydroelectric industry include the following services:

Generator Rebuilding and Rewinding

We know that reliable generator operation is crucial to hydroelectric operations. Our extensive expertise allows us to provide rewinding and rebuilding services for any brand of generator, both in-house and on-site. Using computer-controlled stripping and winding and custom coil capabilities, our experts can quickly return your generators to their original OEM condition.

Gearbox Rebuild & Repair

Renown Electric works with companies of all sizes to repair and rebuild gearboxes in a variety of generator and motor designs. We know the risks posed by poor gearbox alignment, vibration, heat generation, and out-of-spec fits, which is why we work to ensure that your gearbox is operating smoothly and efficiently at all times.

On-Site Repair

At Renown Electric, we understand that some generators must be repaired on-site. We work closely with our customers to conduct vibration analysis, balancing, laser alignment, and maintenance management programs that ensure that your hydroelectric generator is operating efficiently. Our on-site repairs are conducted quickly by skillful technicians with no need for assistance from outside vendors.

Preventative and Predictive Maintenance

Renown Electric is committed to ensuring that our customers receive quality preventative and predictive maintenance to keep their equipment operating reliably at all times. With maintenance services such as vibration and winding analysis, we can help you avoid expensive repairs, costly downtime, and unnecessary equipment replacements.

Expert Motor and Generator Services from Renown Electric

With more than 30 years in the industry, Renown Electric has the knowledge, skill, and equipment to provide superior generator and motor repair and maintenance services to our customers in the hydroelectric industry and beyond. We maintain ISO 9001:2015 and CSA certifications, as well as cutting-edge QA testing and inspection technology to ensure that our repairs meet and exceed even the most stringent OEM specifications. To learn more about our expert maintenance and repair services, contact us today!