How to Save Money on Your Electric Motor

Electric motors are the power sources regulating performance, speed, and torque in some of our most important commercial, residential, and industrial machines. But they’re also the single largest consumers of all electricity and, if not maintained properly, can cause costly downtime.

Fortunately, there are several steps you can take to improve the life and performance of your electric motor, and cut costs significantly. These include:

1. Soft Starts

Without the use of a VFD, three-phase motors can start in three ways:

- Hard start: A direct-on-line start with a very high starting current (6-10 times the rated motor current). This start spurs the motor to get to full speed instantaneously, which can cause belt slippage, heavy wear on bearings and gears, and possible damage to other components in the system;

- Star delta start: Uses contactors and a timer to switch between star-position for starting (using 30% of starting current and 25% starting torque,) then moving to delta for full load;

- Soft start: Gradually applies power to the motor and minimizes the initial jolt.

Soft starts are the safest and most efficient of the three, protecting the facility from blown fuses, excessive voltage, and compromised electrical flow for other warehouse applications. Soft starters use thyristors, semiconductors, and silicon controlled rectifiers to control temperature shifts and electrical current flow as the motor starts, reducing the risk of electrical, technical, and mechanical failure.

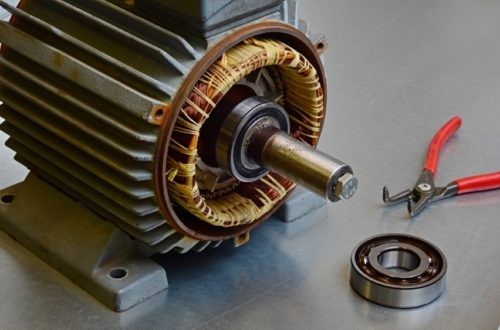

2. Motor Rewinding

Rewinding a blown or burnt out motor can be a cost-effective and time-saving alternative to investing in a full replacement. Although some are weary of this practice, rewinding a motor, when done correctly, will allow for full restoration of the system’s operational efficiency.

3. Motor Drive Maintenance

Variable Frequency Motor Drives (VFD’s) convert electrical energy into mechanical energy, offering controls to regulate speed and torque. In fact, a properly functioning variable frequency drive can delivery up to 55% in energy cost savings.

Unfortunately, many businesses put off motor drive maintenance until a system experiences a catastrophic failure. The resulting costs from a complete motor replacement, as well as lost profits from production downtime during installation, are often much more expensive than the price of routine maintenance and repair would have been. If you experience electric motor drive problems, take care of them early to avoid costly repair services.

Want to Learn More?

Renown Electric’s team of over 40 experts is committed to serving a diverse range of electric motor applications for a variety of industries around the world. Our eBook, 6 Ways to Save Money on Electric Motors, shares additional motor money-saving tips to help you cut costs.