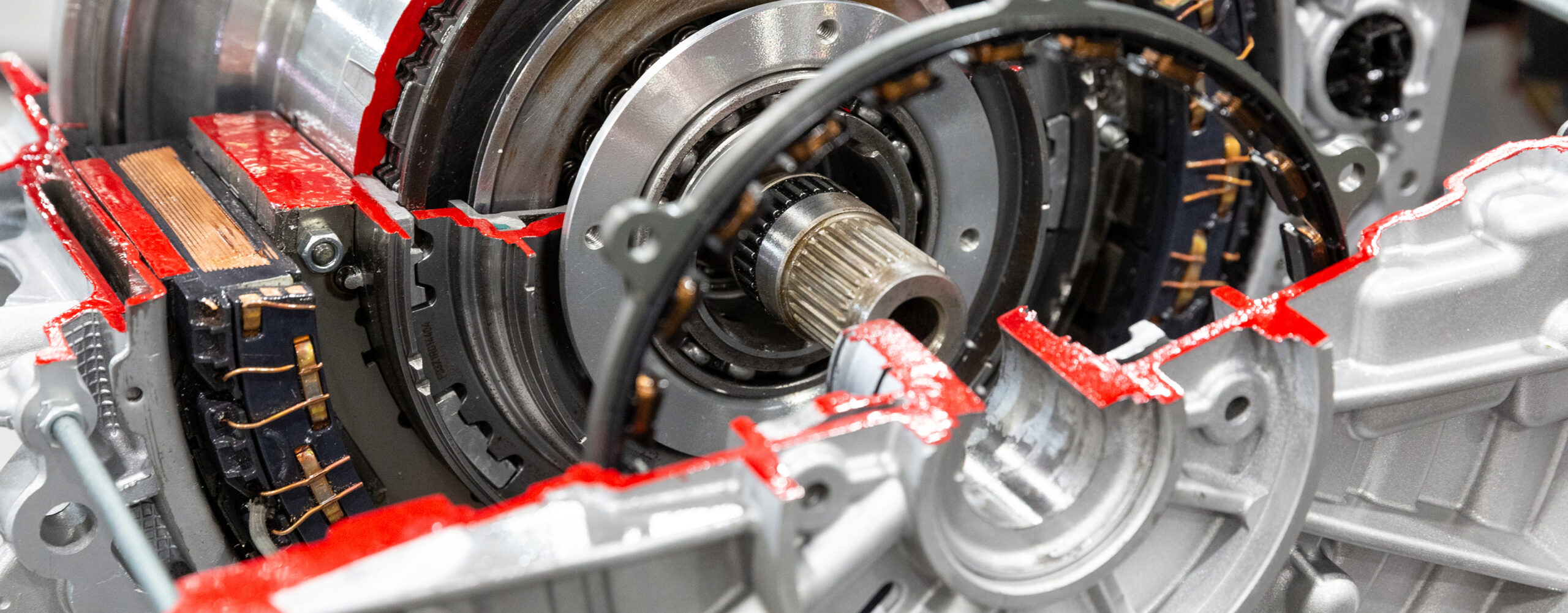

Most modern electric motors run via a variable frequency drive (VFD) for AC motors and DC controller (usually SCR-based) for DC motors, which are used to control motor speed and/or torque. While motor controllers save up to 55% in energy costs, they can also create a large amount of electrical and audible noise. This electrical noise manifests as Common Mode Current that can cause a great deal of fluting, frosting, lubrication breakdown and other damage to the bearings.

Here’s why: After receiving a digital signal from the controller, the signal runs through a switch in order to create a signal that the motor can use. The switch, usually an insulated-gate bipolar transistor (IGBT) for AC motors or Silicone Controlled Recifier (SCR) for DC motors, then creates a signal for the motor that causes the electrical noise superimposed on the control signal for the motor.

The noise manifests as “voltage spikes” — at least one for every signal conversion switch at the set switching frequency — the spikes travel from the controller to the motor and are ultimately discharged via the shortest path to ground, usually through the motor bearing but can also jump from stator to the rotor. Over time, this action and the vibration it generates induce bearing damage.

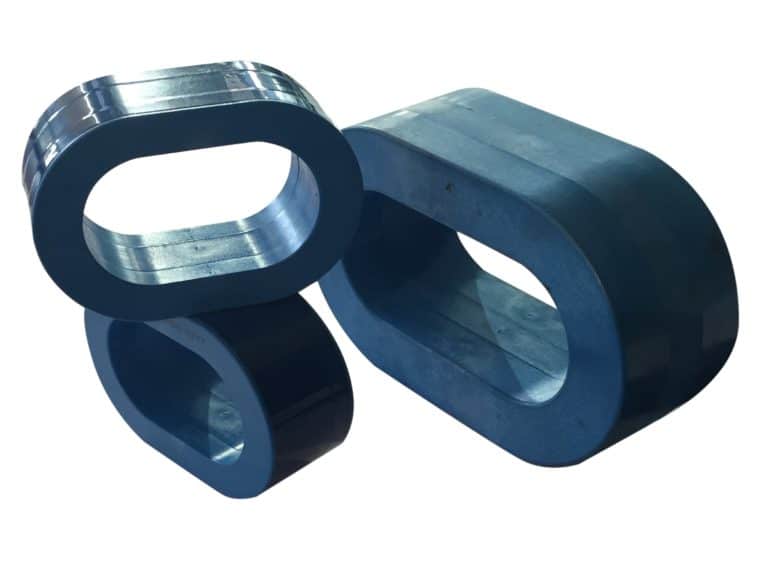

Renown Electric Motors and Repair wanted to seek out and test for a solution to this problem. We investigated the use of CoolBLUE inductive absorbers, also known as common mode chokes, and how they could reduce the high frequency currents that VFDs and DC controllers produce, thus reducing or eliminating bearing fluting and other damage to a motor.

Equipment

CoolBLUE Inductive Absorbers & NaLA Noise Line Absorbers

Test Motors (DC):

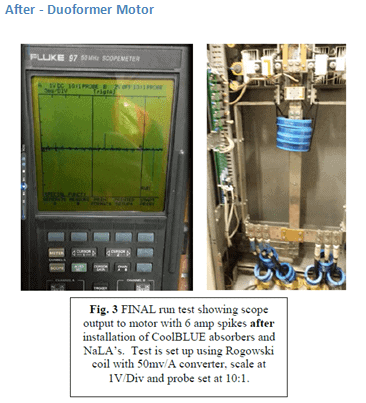

- 780 HP DC motor on a DuoFormer in a paper plant (approx. 260 feet of cable).

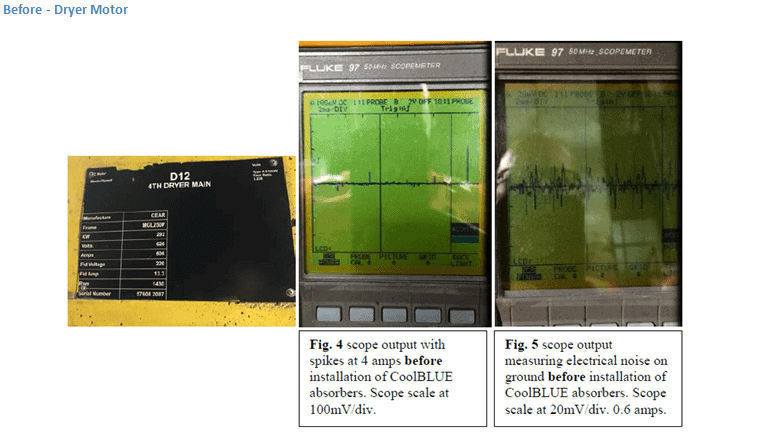

- 390 HP DC motor for a 4th Dryer drive motor system (approx. 100 feet of cable).

Test Motor (AC):

40 HP AC induction motor with encoder feedback controlling a chill roll on a high-speed printing press.

Objective

The primary objective was to seek out and test a solution to the destructive electrical noise generated by VFDs and DC controllers that leads to premature motor bearing failure. Specifically, the goal was to demonstrate that CoolBLUE inductive absorbers could effectively reduce the high-frequency common mode currents to levels within the safe operating range for motor bearings, thereby extending bearing life and reducing maintenance.

Project Duration

The duration of the project is not explicitly stated, but it involved multiple tests across different motor systems (two DC, one AC) and a process of before-and-after measurement.

Challenge (DC)

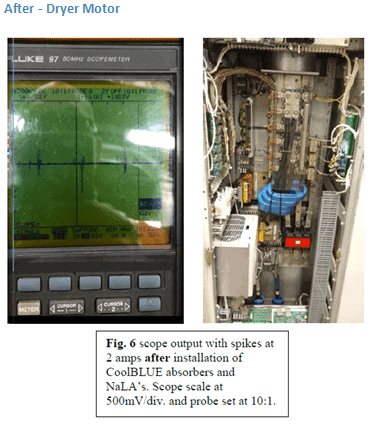

DC motors controlled by SCR-based controllers generate substantial electrical noise. This noise manifests as high-frequency Common Mode Current, which seeks the shortest path to ground, typically discharging through the motor’s bearings. This action is akin to high-speed rotary Electrical Discharge Machining (EDM), causing bearing damage (fluting, frosting, lubrication breakdown) and premature failure. Baseline tests on the 780 HP DuoFormer motor showed current spikes of 20 amps at the drive output and 4 amps on the motor’s ground wire. The 390 HP 4th Dryer motor showed spikes of 4 amps at the drive output and 0.6 amps on the ground.

The Solution (DC)

The chosen solution involved the application of CoolBLUE inductive absorbers and NaLA noise line absorbers, which were strategically installed on the output cables of the DC controllers. The core of the solution was to measure the common mode current after the installation using the Rogowski coil and oscilloscope, thereby quantifying the devices’ effectiveness and determining the precise level of attenuation achieved in the high-frequency current spikes.

Challenge (AC)

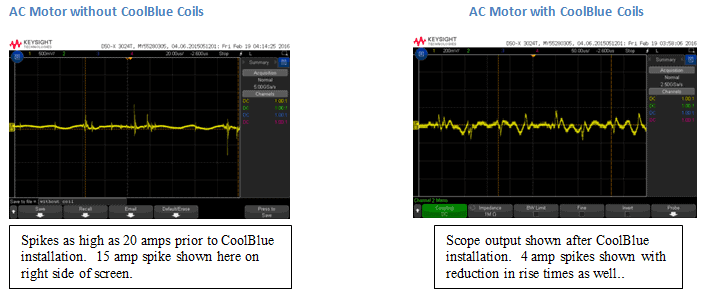

AC induction motors controlled by VFDs using IGBTs also produce significant electrical noise (Common Mode Current). This noise caused a nuisance 40 HP motor controlling a chill roll to suffer regular failures due to electrical pitting confirmed by the bearing manufacturer. The discharges generated heat, created small craters on the contact surfaces, deteriorated the lubricant (often turning the oil black), and increased the bearing’s noise and vibration. The baseline current measurement was approximately 20 amps.

The Solution (AC)

To address the chronic bearing failure caused by electrical pitting in the 40 HP AC motor system, the intervention involved installing CoolBLUE and NaLA absorbers directly onto the drive output cables of the controlling VFD. Once installed, the process concluded with post-installation measurements being rigorously taken. This allowed for the direct comparison of the pre- and post-installation current levels to accurately quantify the reduction in common mode current achieved by the absorbers.

Process

The testing involved a three-step process for both the DC and AC motor applications:

Baseline Measurement: Measure the magnitude of the high-frequency Common Mode Current (voltage spikes) on the drive output and/or the motor ground wire before the installation of any absorption devices, using the Rogowski coil and oscilloscope.

Installation: Install the CoolBLUE and NaLA inductive/noise line absorbers on the drive output cables.

Post-Installation Measurement: Repeat the current measurement on the drive output and/or motor ground wire after the absorbers were installed to quantify the reduction in Common Mode Current.

Get in Touch with our Skilled Team

No matter your industry or application, we’re here for you. Contact us to learn more about our extensive capabilities, and how we serve clients across industries to ensure their motors are operating at their best.