One of our valued steel manufacturing customers approached us with a unique request: to reverse engineer a large 2200HP Westinghouse Electric Company DC armature which involved 3 phases.

The six-month timeline for the Westinghouse Electric Company DC armature rebuild began with a complex reverse engineering phase. After a steel manufacturing customer presented Renown Electric with the challenge of rebuilding a large 2200HP DC armature, the team, with an engineering partner, conducted meticulous on-site measurements and data collection. This critical information was used to develop a comprehensive set of build drawings, which, once approved, allowed for the initial manufacturing of key structural components like the shaft and spider frame. Following the shaft’s successful completion, the focus shifted to producing the internal elements, including custom-made segmented core laminations, vent plates, and coil support rings—all manufactured to the original Westinghouse specifications and ready for installation to form the complete armature core.

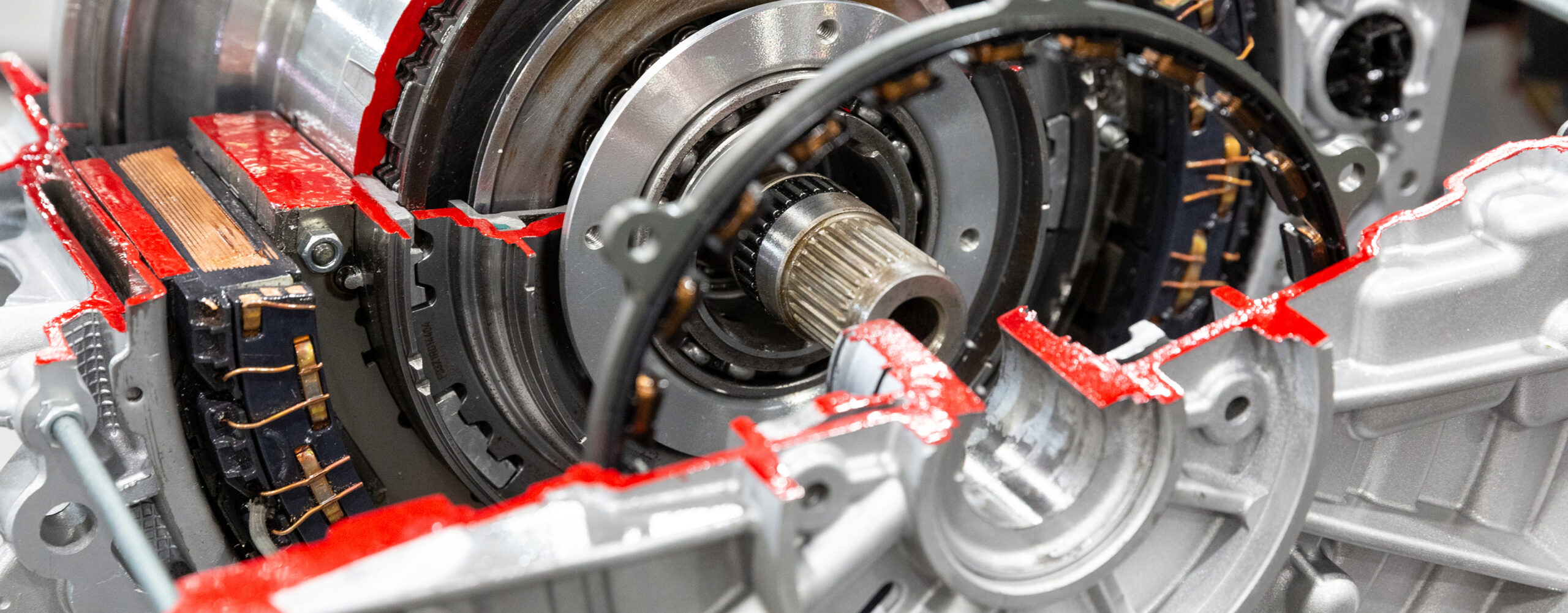

With the armature core stacked and secured, the project moved into the intricate electrical and assembly stages. Renown Electric manufactured the armature coils and equalizer ring in-house, ensuring they met the precise requirements of the original design. After receiving and installing the new commutator, the winders prepared the core and meticulously installed all of the coils. The final electrical connections were secured by connecting the main coils to the commutator risers using torch brazing, and the rear coils to the equalizer ring. Following these crucial steps, which included insulation, testing, and inspection, the final stage involved applying the armature and core banding on a specialized 9′ swing banding machine, using B-stage material to meet the original manufacturer’s specifications and successfully completing the comprehensive three-month rebuild.

Equipment

Westinghouse 2200 HP Large Armature

Objective

Reverse engineering Westinghouse armature for major

steel manufacturing client.

Project Duration

6 months

Pictures throughout the rebuild process:

Challenge

Our team, along with a partner engineering firm, traveled to the customer’s site to meticulously measure and collect all necessary data for the armature. Once we had this critical information, we collaborated with the engineering firm and the customer to develop a comprehensive set of build drawings.

With the drawings approved, we’re now in the early stages of manufacturing the key components, including the shaft and spider frame (as seen in the pictures).

The lathe originally planned for machining had a breakdown and it would be over 1 year before we could get time back on that lathe. We worked to find alternative forge and machining capacity to keep the project moving forward.

Process

Once we secured a forge and lathe capacity along with the appropriate quality audit, we were able to begin the manufacturing process of the shaft and components that make up the mechanical portion of the armature. In parallel, laminations were ordered, commutator was ordered and we manufactured coils and riser.

Following the successful completion of the shaft manufacturing, we’ve seamlessly transitioned to the next stage of this new build with the manufacturing of the coil support rings and the custom-made segmented core laminations and vent plates.

These laminations and vent plates are manufactured to the same tolerance of the original design. The core packs will also be to the original specifications of the Westinghouse design.

We received and installed the new commutator as well as completed the manufacturing of the equalizer ring and armature coils in our in-house coil manufacturing department.

Our winders have prepared and insulated the slots and coil support rings and have recently completed installing all of the coils. Our next process is to begin connecting the armature coils to the commutator risers and the rear coil connections to the equalizer ring.

We finished installing the armature coils and connecting the rear equalizing ring, manufactured in-house. Renown Electric Motors & Repair Inc. winders are now connecting the main coils to the commutator risers using torch brazing for a secure bond.

Nomex insulation and two rows of weaving are added between the riser extensions.

Get in Touch with our Skilled Team

No matter your industry or application, we’re here for you. Contact us to learn more about our extensive capabilities, and how we serve clients across industries to ensure their motors are operating at their best.