Brush Survey Field Services

Part of maintaining Electric Motors & Generators includes taking a brush survey to ensure that carbon brushes are in good working order. Renown Electric provides a brush survey field service to diagnose and troubleshoot motor problems and to repair equipment before any serious problems can occur.

A carbon brush, or motor brush, is a vital component of motors and generators. It is a sliding contact that transmits an electrical current from stationary to rotating parts. Consisting of one or more carbon blocks, the brushes need to be seated properly and maintained to ensure the best performance.

With our brush survey, we provide the means to evaluate the condition and operating efficiency of the brush. A carbon brush has mechanical, electrical, and physical parameters that must be met; our team assesses these parameters when examining how the motor functions.

Using the wrong slip ring or commutator are just two mechanical issues that can negatively affect carbon brush functionality. During our survey, we make sure the ring or commutator provides the right amount of friction, is defect-free and properly chamfered, and the run out is within the acceptable limits (Figure 1). Carbon brush pressure is calibrated for accuracy, and brush holders are inspected for the right height and clearance. Machines are evaluated for excessive vibrations so that misalignment of parts does not cause damage to the carbon brush.

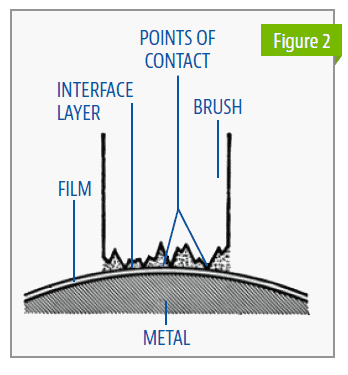

The electrical system within the motor/generator is evaluated for voltage or contact drop, commutation in DC machines, and distribution of current brush contact surface, current density, and resistivity. If any of these factors are not at the correct levels, this can lead to brush damage—that’s why we carefully check that all electrical conditions are properly adjusted (Figure 2).

Our survey team performs thorough checks of the physical/chemical conditions around the motor to ensure that humidity, corrosive vapors or gases, oils and hydrocarbons, and contaminants don’t affect the carbon brush.

Partnering with Renown Electric In-Field Brush Surveys

At Renown Electric Motors & Generators Repair, Inc. we understand that each electric motor and generator system has different operating requirements and uses. With over 40 years of experience, our team has the in-depth knowledge necessary to ensure that you have the perfect brush material and design for your electric motors and generators.

Advantages of Carbon Brushes

Carbon brushes have been a mainstay for transferring current in electric motors and generators for many years. While brush surveys, which assess wear and health of the brushes, are crucial for maintenance, the inherent properties of carbon itself offer several advantages over other methods:

Carbon based brushes have a higher melting point than traditional copper brushes, so they can withstand much higher operating temperatures. This makes them ideal for electrical motors in high-temperature applications.

Carbon brushes are softer than other brush materials, which reduces potential wear on the rotating components of the motor. This helps to reduce overall maintenance, repair, and replacement costs, and extends the service life of Electric Motors & Generators components.

Carbon brushes exhibit a negative temperature coefficient, so there is less electrical resistance as the operating temperature of the motor rises, thereby ensuring smooth and reliable current flow.

Carbon brushes are malleable and will form themselves to the rotating components with which they interact. This allows for more even contact and less potential for uneven wear on rotating parts.

The low friction coefficient and strong fibers in carbon brushes make them self-lubricating, so it isn’t necessary to add oil or other lubricants. This makes carbon brushes ideal for use in dry operations in which liquid lubricants are contraindicated.

Different Grades of Carbon Brushes

A carbon brush is an electrical conductor that transmits current from stationary motor wires to rotating components within the motor. Since carbon brushes can transmit electrical current without sparks, they are ideal for current transmission in a variety of motors and generators. In order to meet the varied needs of different systems, carbon brushes are available in a wide range of grades and designs. Each grade is specifically designed to meet particular conducting needs. Some motors or generators may require more than one carbon brush.

Carbon has largely replaced copper as the ideal material for motor brushes. Unlike copper, carbon-based brushes exhibit a high level of contact and arc resistance. In addition, carbon brushes create less friction than their copper counterparts, facilitating smoother overall operation.

To derive the desirable characteristics for each grade, the raw material is exposed to different temperatures, pressures, and processing times. Carbon brushes are divided into grades based on their materials and designs:

- Carbon graphite

- Electrographite

- Graphite

- Metal graphite

Carbon brushes in Electric Motors & Generators transfer current from the stationary parts of a motor to rotary components. Although they are called brushes, carbon brushes actually consist of a solid block of carbon with bevels or angled corners tailored to fit the specific parameters of the motor in which they are used.

The flow of current from stationary to rotating components within an electrical motor is more easily controlled through the use of carbon brushes. A spring mechanism holds the carbon brush against rotating components, such as rotary shafts, commutators, or slip rings. Small, evenly spaced contact spots on the brush limit the amount of electricity conducted at a given time, ensuring a steady and reliable flow of current without undue wear on any one area of either the brush or rotating parts.

When using carbon brushes in electrical motors, it is important to perform regular and attentive maintenance to ensure optimal operational efficiency and service life. Many equipment malfunctions can be attributed to carbon brush failures caused by lack of proper maintenance. You can avoid unwanted repairs and downtime by understanding the maintenance and replacement processes for your carbon brush.

Regular Motor Cleaning

Keep your carbon brushes in ideal form by regularly cleaning the motor with an air compressor. This prevents unwanted contaminants such as dust and debris from interfering with brush operation.

Use the Right Tools

Carbon brushes require special care, and a variety of tools have been developed to help you ensure that your brushes are in perfect working condition. Carbon brush maintenance tools include:

- Garnett paper

- Brush seating and grinding stones

- Mica undercutters and saws

- Slotting files and scrapers

- Finishing tools and support frames

With the right tools and a regular cleaning regimen, carbon brushes can enhance your Electric Motors & Generators applications and increase operational and energy efficiency.

Guide to Carbon Brushes for Motors & Generators

Renown Electric offers a free, technical guide that provides a detailed review of carbon brushes for use in motors and generators.

Get in Touch with our Skilled Team

No matter your industry or application, we’re here for you. Contact us to learn more about our extensive capabilities, and how we serve clients across industries to ensure their motors are operating at their best.