Servicing Any Type of Single-Stage and Multi-Stage Gearboxes

At Renown Electric Motors & Generators Repair Inc., we have been rebuilding and repairing gearboxes since 1984. Whether it is at one of our state-of-the-art repair facilities in Concord, Ontario, or on-site, Renown dedicates a great deal of expertise restoring gearboxes to OEM specifications.

Renown can service any type of single-stage and multi-stage gearboxes, including worm, helical, or bevel helical geared. Our expert staff utilizes a wide variety of modern calibrated equipment.

When a gearbox’s alignment or internal fits are out of spec, or when they have high levels of vibration and heat generation, your efficiency and production levels are bound to plummet.

Replacing a faulty industrial gearbox can take up much of your budget as well as cause excessive downtime. Instead of squandering precious money and time, many companies and facilities opt to rebuild malfunctioning gearboxes.

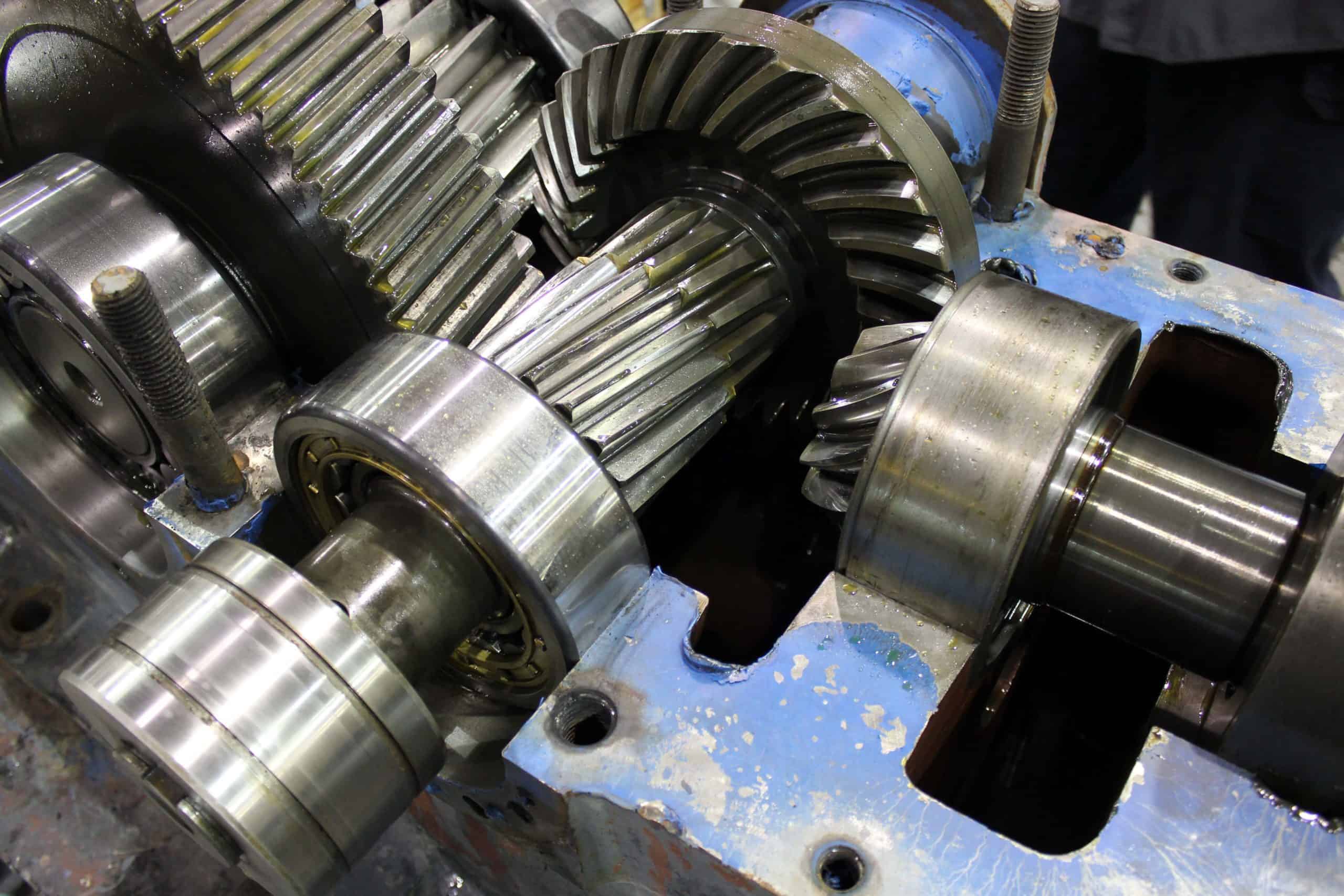

Below is an example of a gearbox before and after repair by Renown Electric:

Gearbox Before Repair

Gearbox After Repair

Rebuild & Repair Your Damaged Gearboxes

If you are dealing with gearboxes that no longer operate at their highest proficiency, Renown can help you return your equipment to OEM specifications. Renown offers 24-7 customer service, a collection of service and delivery vehicles, and certifications that include ISO 9001:2015, CSA qualifications for hazardous location servicing, and compliance with various procurement solutions.

Serving a Variety of Industries for Gearbox Repair

Renown’s professionals work closely with companies—both small and large—in a number of different critical industries that demand high-levels of consistency and safety, which include:

- Aggregate

- Elevators and Escalators

- Construction

- Cutting & Shredding

- Food Processing

- Hydroelectric

- Manufacturing

- Power Generation (wind, hydroelectric, nuclear)

- Mining & Milling

- Oil & Gas Drilling

- Petroleum Processing

- Plastic Extrusion

- Pulp and Paper

- Steel and Tube Processing

- Water & Wastewater Treatment

- Wind Power

Our Other capabilities include:

- Detailed and Exhaustive Testing

- On-Site Laser Alignment and Balancing

- On-Site Vibration Analysis Programs

- Predictive Maintenance Programs

- Quick Turnaround Times

- Easy and No-Charge Job-Site Pick-Up and Return in Southern Ontario

5 Reasons for Using Laser Alignment for Your Motor Repairs

Correct alignment of components within a motor ensures proper operation and can boost its performance. Learn more about the industry-leading method to correct alignment.

Get in Touch with our Skilled Team

No matter your industry or application, we’re here for you. Contact us to learn more about our extensive capabilities, and how we serve clients across industries to ensure their motors are operating at their best.