Sheave Regrooving & Manufacturing is One of Our Top Specialties

Since 1984, our dedicated elevator experts have been returning sheaves to their OEM specifications, as well as manufacturing ideally matched or upgraded replacement parts.

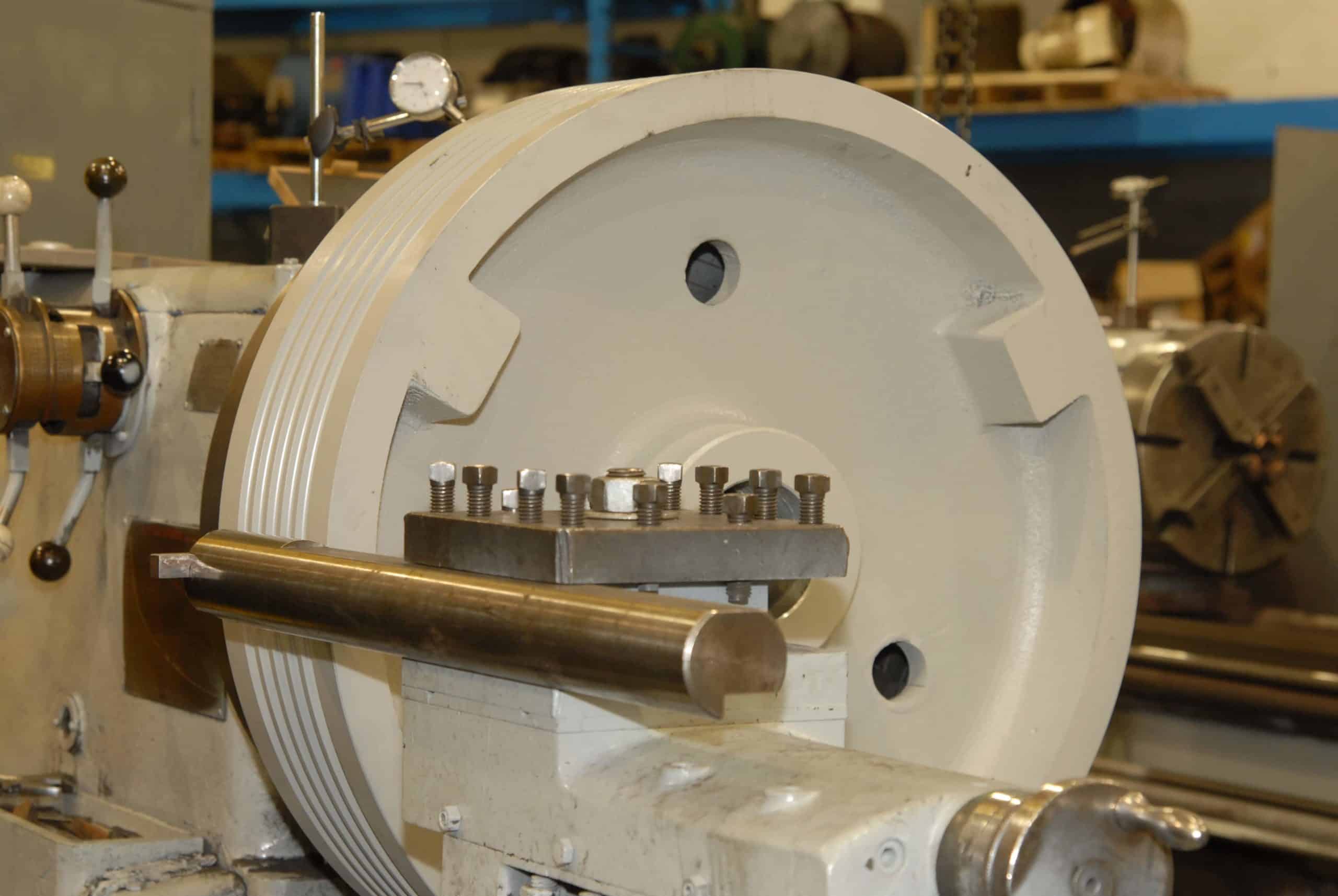

We provide high-quality sheave regrooving and manufacturing in a timely and cost-effective fashion to all clients, no matter the size of their project. Our in-house machine shop and our on-site services allow for us to repair, regroove, and manufacture industry-leading U Groove, Undercut U, and Progressive V sheaves.

Renown has all the certification and qualification necessary to guarantee you are getting the highest quality products and service including:

- CSA Qualification for the Repair and Service of Motors and Generators in Hazardous Locations

- ISO 9001:2015

- ISN, BROWZ, EXIROS, and QUADREM Compliance

Keep Elevators Running at Peak Performance for Efficiency and Safety

Today’s industrial and commercial facilities demand a great deal from modern elevators; with movement towards decreased power consumption, reduced equipment costs, increased space utilization, and constant usage, elevators are under unbelievably high levels of scrutiny.

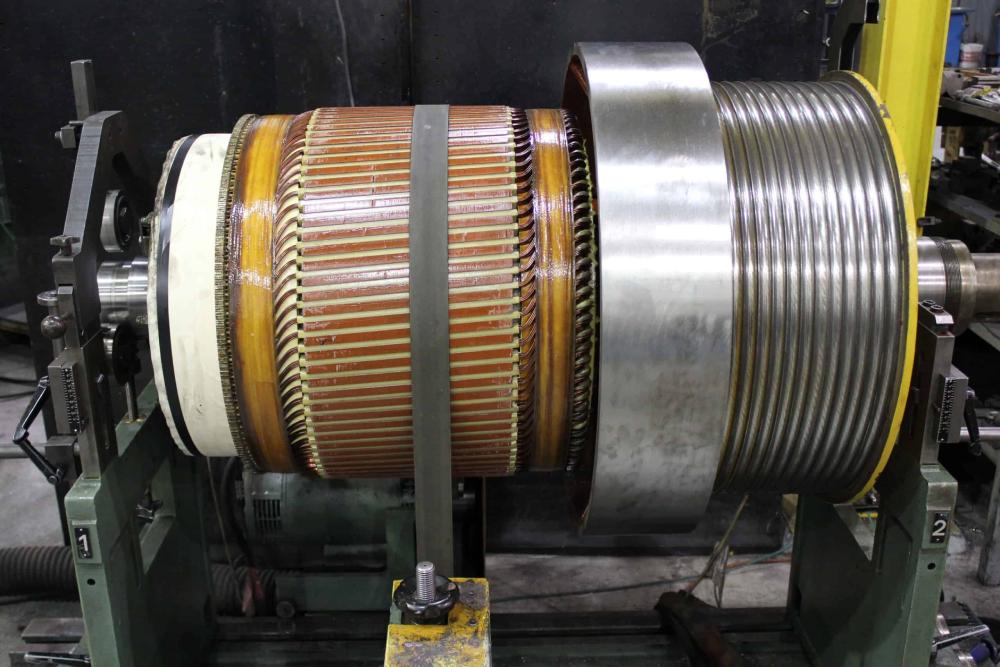

Due to these factors, and more aggressive sheave groove profiles, one of the keys to proper elevator maintenance is sheave regrooving. A worn sheave causes additional wear on the ropes that are at the heart of elevator operation, so they demand more maintenance than ever before. It is important to remember that all sheaves will need to be regrooved at least once during their service lives, so it is critical to have the right team supporting you.

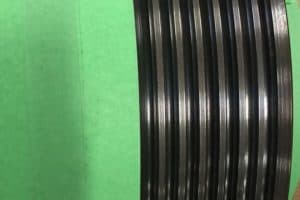

Our on-site service includes evaluation of sheave grooving for proper rope fit. Sheaves should be checked annually and if groove wear is seen, regrooving may be necessary. There are a number of factors that affect the need or frequency of regrooving. Different groove types wear ropes at different rates. Our experts are able to recommend the correct groove to meet requirements and optimize sheave life. Proper and correct grooving extends the life of the rope. Ensuring that there is the right groove and the right amount of traction will lead to less maintenance. Generally, regrooving is required at least once during the elevator’s service life. The frequency of this is dependent upon factors such as groove type and number of cycles.

Before Regrooving

After Regrooving

Ensure Cables Have Enough Grip on the Sheave to Operate Effectively

As ropes and drive sheaves age, sheave regrooving is a common repair. With extensive experience in regrooving elevator sheaves, we offer valuable technical knowledge that is compatible with new developments in elevator design and construction. At Renown Electric, we have capabilities suitable for all makes and models of elevators.

Increasing demands on elevator use, as is common in most modern buildings, leads to increasing wear on the equipment. We provide a solution and service to keep elevators in best working condition.

Complement Your Sheave Regrooving Service with the Vertima Balance Hydraulic Rope Equalizer

After investing in sheave regrooving to ensure optimal rope-to-groove interface, the next logical step to maximize your elevator system’s efficiency and longevity is to ensure perfectly uniform rope tension. Unequal rope tension is a leading cause of premature rope and sheave wear, rapidly undoing the benefits of your regrooving service.

We highly recommend installing the Vertima Balance Hydraulic Rope Equalizer as a permanent, maintenance-free add-on during re-installation. This advanced German-engineered device is designed to eliminate all issues associated with unequal rope length in your system, delivering unmatched precision and protection.

Key Features and Benefits

The Vertima Balance provides a host of advantages that secure your investment in regrooving and improve overall elevator performance:

- Maximize Rope and Sheave Life: By ensuring all ropes bear an equal load, the Vertima Balance minimizes abrasion on your newly regrooved traction sheave or pulley. This can lead to a rope service life up to 50% longer, significantly cutting replacement costs.

- Maintenance-Free and Auto-Remediating: This device operates within a closed hydraulic system, requiring no routine or preventative maintenance. It features real-time detection and immediate remediation for inconsistent rope tension, eliminating the need for time-consuming tension inspections or manual configuration settings.

- Superior Ride Comfort and Performance: The equal dispersion of cable tension results in a much smoother, quieter ride for users, with less bucking, reduced shearing, and improved stopping accuracy at the holding position.

- Flexible and Fast Installation: The unit typically ships fully assembled and is ready to install. It can be mounted in nearly any position (on the cabin, in the machine room, or upside-down in the machine room for 2:1 applications) and integrates seamlessly with existing equipment, making for a quick and easy service addition.

Protect your newly regrooved sheaves and secure the longevity of your ropes by incorporating the Vertima Balance into your modernization or repair project.

Renown Electric has a free guide to help you learn

how these instruments equalize tension across all ropes involved,

to prevent costly wear and tear of your cables and sheaves

We Regroove Sheaves In Any Groove Type

The U-groove is found in many older installations while the Undercut U-grooves and Progressive V-grooves increase traction and are favored in modern installations.

Sheave regrooving capability includes:

- On-site sheave and rope assessment

- Measurement of sheave grooves

- Measurement of rope

- Determination of sheave regrooving process

- Removal of sheave to perform appropriate regrooving

Don’t Replace, Regroove!

Save money on motor sheaves and extend motor sheave life with on-site regrooving services. At Renown Electric, our highly trained and skilled personnel provide 24-7 customer service for our in-house and on-site elevator repair and maintenance services. To discover how Renown can improve the efficiency and safety of your elevators, please contact a representative today.

Learn the Benefits of Regular Sheave Maintenance

We invite you to download your free copy of our ebook, Regular Sheave Regrooving & Maintenance Benefits for Your Elevator, walking you through key cost-saving processes and benefits of regular sheave maintenance.

Get in Touch with our Skilled Team

No matter your industry or application, we’re here for you. Contact us to learn more about our extensive capabilities, and how we serve clients across industries to ensure their motors are operating at their best.