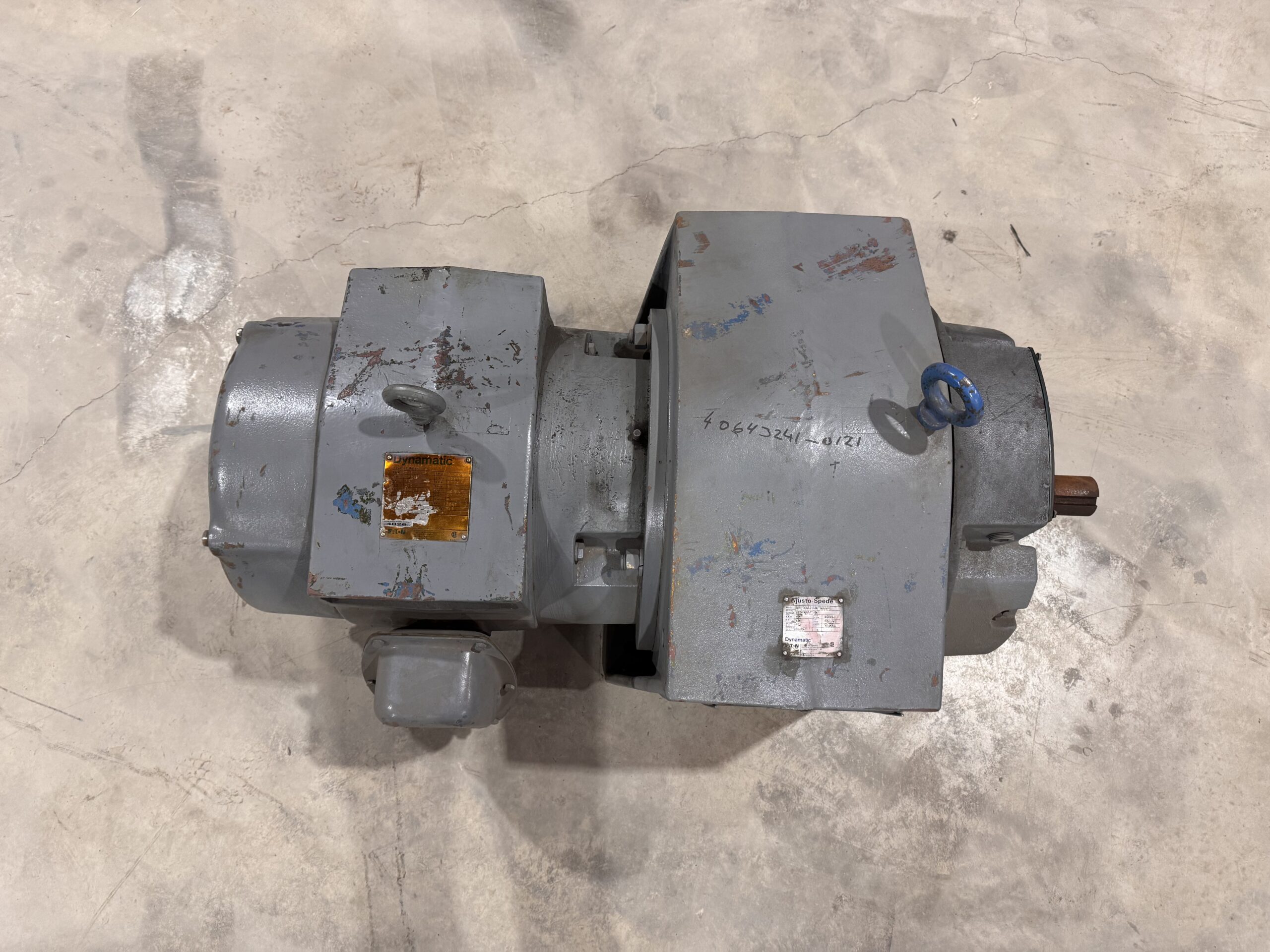

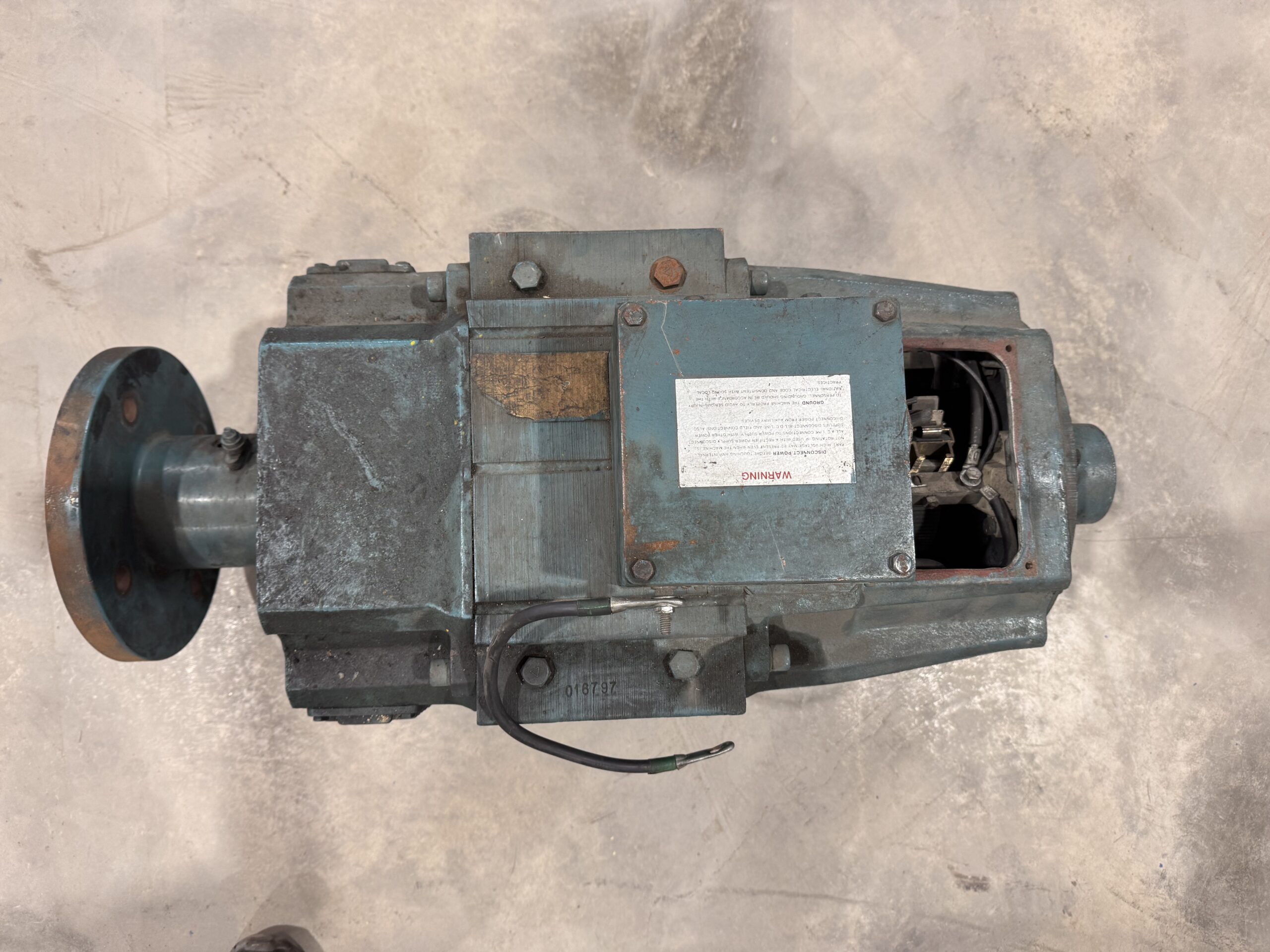

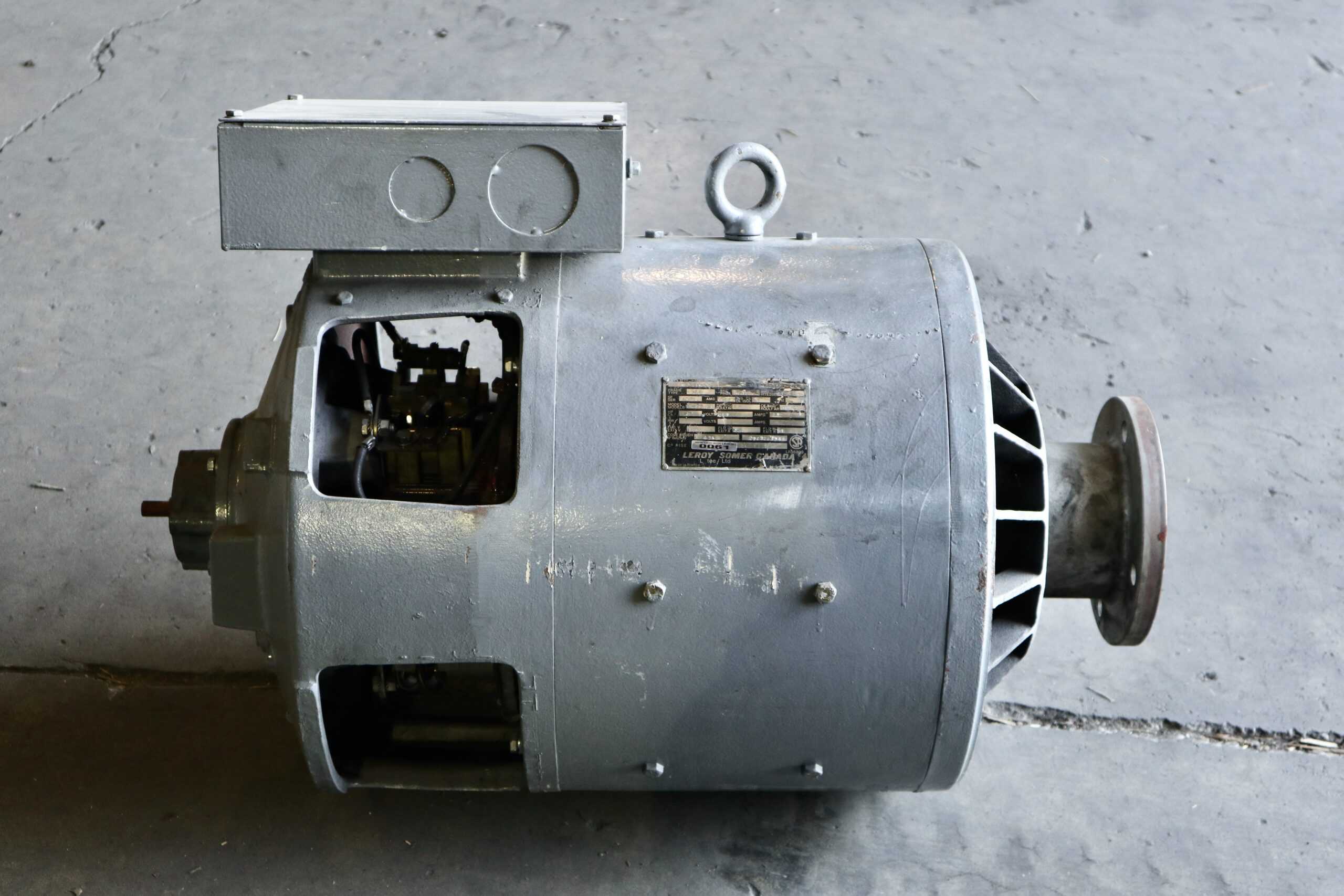

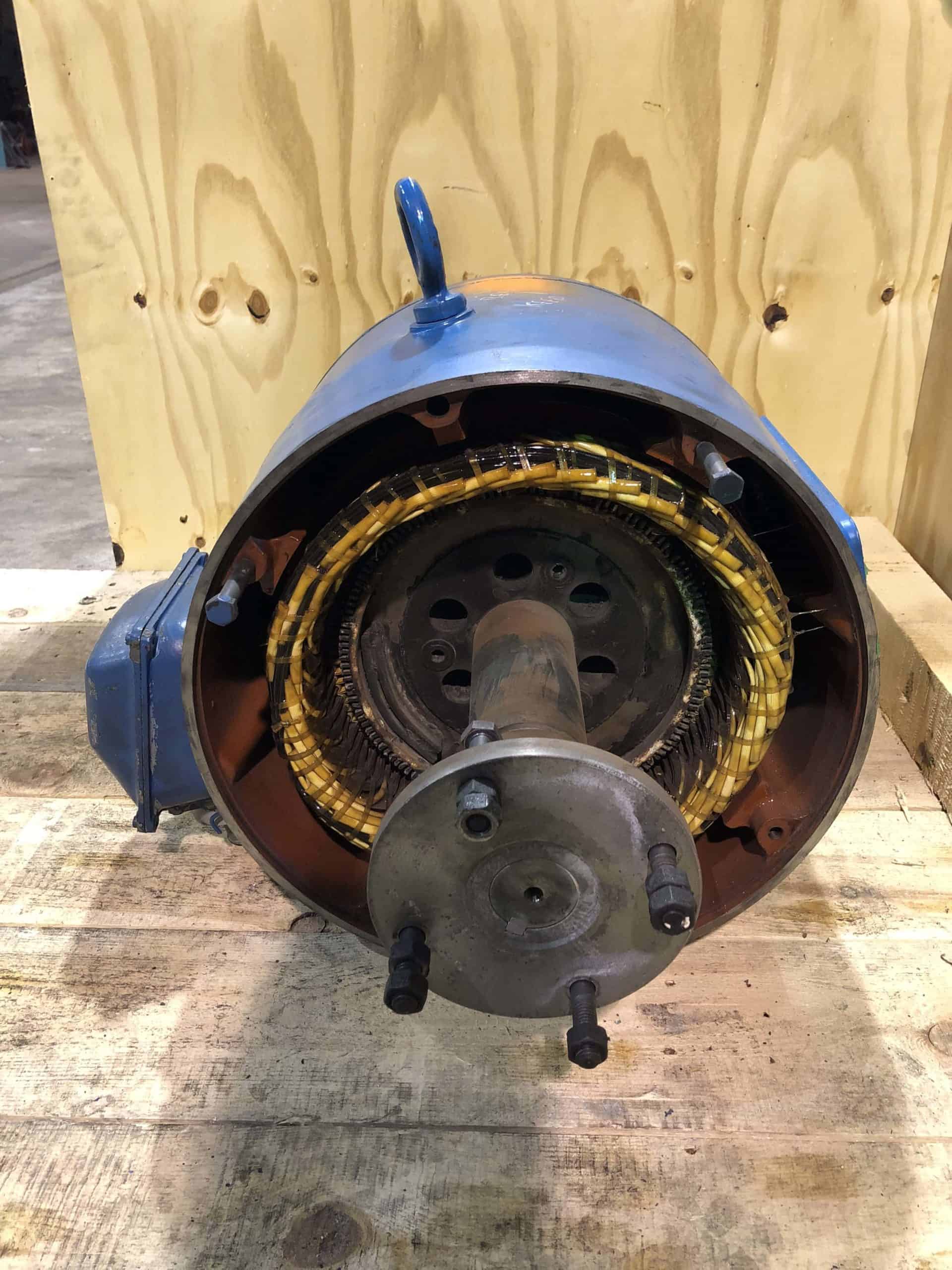

Reliance 3HP 1750RPM 1611ATC #0442

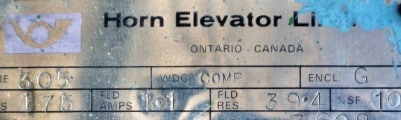

Renown Electric supplies a diverse selection of in-stock motors, elevator controls, elevator parts, AC & DC drives, and more. We also support equipment from major manufacturers such as General Electric, Otis, Westinghouse, WEG and many others.

If you cannot find the product you need, please contact us with your requirements.

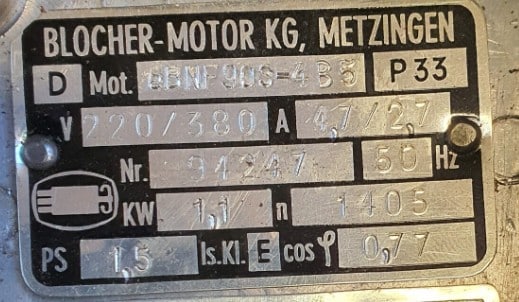

Specifications

Motor Brands (MTR MFG)

Reliance

HP

3

RPMs

1750

Volts

180

Field Volt

100/200

Location

Bin L4

Serial #

M28403-OC T2

Amps

15.3

Field Current

1.2/0.6

Type

TR

Frame

1611ATC

Related Products

Center Bonded Mounts STA Series

- Flat Top Recessed Bumpers

- Rounded Top Recessed Bumpers

- Large Bumper Pads

- Grommet Bumper A

Get in Touch with our Skilled Team

No matter your industry or application, we’re here for you. Contact us to learn more about our extensive capabilities, and how we serve clients across industries to ensure their motors are operating at their best.