Are Your Electric Motors & Generators Healthy?

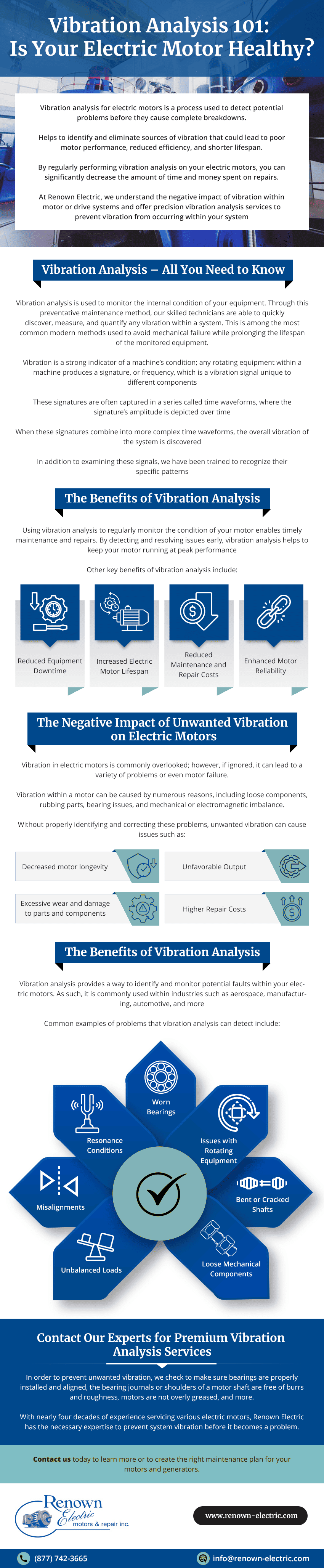

Vibration analysis for Electric Motors & Generators is a process used to detect potential problems before they cause complete breakdowns. More specifically, vibration analysis helps to identify and eliminate sources of vibration that could lead to poor motor performance, reduced efficiency, and shorter lifespan. By regularly performing vibration analysis on your Electric Motors & Generators, you can significantly decrease the amount of time and money spent on repairs.

At Renown Electric, we understand the negative impact of vibration within motor or drive systems and offer precision vibration analysis services to prevent vibration from occurring within your system. With nearly four decades of experience servicing various Electric Motors & Generators, Renown Electric has the necessary expertise to prevent system vibration before it becomes a problem.

Vibration Analysis – All You Need to Know

Vibration analysis is used to monitor the internal condition of your equipment. Through this preventative maintenance method, our skilled technicians are able to quickly discover, measure, and quantify any vibration within a system. This is among the most common modern methods used to avoid mechanical failure while prolonging the lifespan of the monitored equipment.

Vibration is a strong indicator of a machine’s condition; any rotating equipment within a machine produces a signature, or frequency, which is a vibration signal unique to different components. These signatures are often captured in a series called time waveforms, where the signature’s amplitude is depicted over time. When these signatures combine into more complex time waveforms, the overall vibration of the system is discovered. In addition to examining these signals, we have been trained to recognize their specific patterns.

The Benefits of Vibration Analysis

Using vibration analysis to regularly monitor the condition of your motor enables timely maintenance and repairs. By detecting and resolving issues early, vibration analysis helps to keep your motor running at peak performance. Other key benefits of vibration analysis include:

- Reduced equipment downtime

- Increased Electric Motors & Generators lifespan

- Reduced maintenance and repair costs

- Enhanced motor reliability

The Negative Impact of Unwanted Vibration on Electric Motors & Generators

Vibration in Electric Motors & Generators is commonly overlooked; however, if ignored, it can lead to a variety of problems or even motor failure. Vibration within a motor can be caused by numerous reasons, including loose components, rubbing parts, bearing issues, and mechanical or electromagnetic imbalance. Without properly identifying and correcting these problems, unwanted vibration can cause issues such as:

- Decreased motor longevity

- Unfavorable output

- Excessive wear and damage to parts and components

- Higher repair costs

What Can Vibration Analysis Detect?

Vibration analysis provides a way to identify and monitor potential faults within your Electric Motors & Generators. As such, it is commonly used within industries such as aerospace, manufacturing, automotive, and more. Common examples of problems that vibration analysis can detect include:

- Unbalanced loads

- Misalignments

- Resonance conditions

- Issues with rotating equipment

- Worn bearings

- Bent or cracked shafts

- Loose mechanical components

In order to prevent unwanted vibration, we check to make sure bearings are properly installed and aligned, the bearing journals or shoulders of a motor shaft are free of burrs and roughness, motors are not overly greased, and more.

In addition to our vibration analysis services, we also offer our i-Alert® Monitoring Solution Sensors, which enable manufacturers and other industrial equipment operators to monitor, troubleshoot, and collect data on various applications using only the i-Alert® sensors and a smartphone. This solution offers a simple and cost-effective way to monitor a large network of systems and equipment to ensure optimal performance.

If you want to stop system vibration before it even begins, it’s time to contact Renown Electric. Our expert staff is available 24 hours a day and 7 days a week to help.

Identify Faulty Components

Industrial manufacturers must ensure that their machinery consistently functions well in order to stay productive. Many companies do so using vibration analysis.

Download eBookNeeding Service?

With shop services in one of our facilities or field services across Canada, our skilled technicians are ready to help.

Contact Us Today