The Renown Electric team now offers CoolBLUE Inductive Absorbers that reduce damage to motor bearings and extend system life for each day of use.

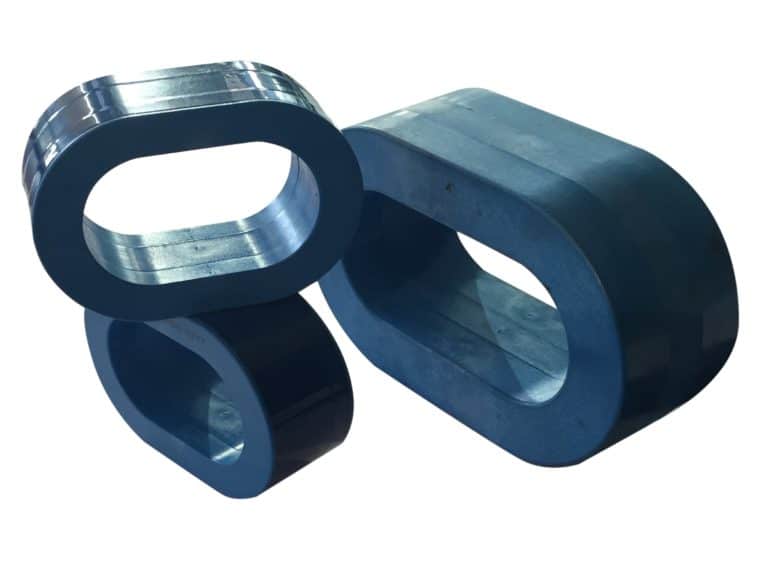

CoolBLUE inductive absorbers are nanocrystalline rings used to protect motor bearings from high-frequency noise emitted by variable frequency drives (VFDs). As the name implies, these absorbers suppress the currents generated by the VFD, and prevent current from reaching levels that will damage the bearing components.

What are CoolBLUE Inductive Absorbers Used For?

VFDs generate high levels of current that may damage motor bearings if left unchecked. Without proper mitigation, the current causes the bearing to fail prematurely, lubrication to fail, and electrical discharge to occur within the system which may cause various unexplained disturbances in the machine. Ultimately, the motor bearing itself will fail, resulting in catastrophic system failure.

It was for these reasons that CoolBLUE inductive absorbers were developed. A recent current-reduction method, CoolBLUE is composed of a nanocrystalline material that absorbs the current before it reaches the bearings. CoolBLUE absorbers provide an easy and highly effective way to protect your motor system components from the damaging currents released by VFD systems.

How Do CoolBLUE Inductive Absorbers Work?

CoolBLUE inductive absorbers are ring-shaped components that can be installed directly on the lead wires between your VFD and the system’s electric motor. They act as a common mode choke, diminishing the reach of common mode currents, transient voltage, and unwanted capacitive current by absorbing the extra voltage and noise created by the VFD and releasing it as dissipated thermal energy. Since they can be applied directly on the wiring assemblies, CoolBLUE inductive absorber rings are easy to install without the need for modifications to the motor or shaft.

Watch Our Video to Learn More:

What is CoolBLUE?

CoolBLUE material is composed of Nanoperm, an iron alloy with a fine crystalline nanostructure. The tiny grain size of CoolBLUE’s Nanoperm material gives the rings their valuable noise-absorbing and electromagnetic properties.

CoolBLUE vs. Shaft Grounding

Although shaft grounding is considered the standard means of redirecting excess current, this method is less effective than CoolBLUE absorbers. Shaft grounding simply redirects the stray voltage to the ground via a different path. Harmful high-frequency current and reflected current from your VFD can still affect your control system, motor and bearings when using traditional shaft grounding.

CoolBLUE inductive absorbers are a more recently developed solution to the problem of high-frequency VFD noise. Rather than allowing the current to continue through the system, they absorb the current, thereby preventing it from ever reaching the motor.

In addition, CoolBLUE Systems offer the following benefits over traditional shaft grounding:

- CoolBLUE does not require complicated installation processes or additional components.

- CoolBLUE cores do not require coating or lubrication, as they are not affected by shaft contaminants.

- CoolBLUE cores are not affected by humidity or other environmental factors that reduce brush contact as in the case of shaft grounding.

- CoolBLUE absorbers are available in a large range of sizes that span the needs of all motor shapes and sizes for easy core selection.

- CoolBLUE cores last the lifetime of your motor, requiring only a single investment and installation per motor.

Benefits of Using CoolBLUE Inductive Absorbers

CoolBLUE inductive absorbers can reduce overall operating costs by diminishing the potential for damage due to excess VFD current. Not only do they help reduce maintenance and repair costs, they also prevent costly downtime. Long-term use can extend the service life of motor bearings by reducing the wear caused by excessive current and vibration. Some of the major benefits of CoolBLUE include:

The high-frequency noise emitted by VFDs may cause a great deal of damage to motor system components. CoolBLUE rings act as a common-mode choke to prevent noise from reaching the electric motor, which significantly increases overall system reliability. CoolBLUE inductive absorbers ultimately reduce wear and tear on motor components, thereby reducing the potential need for unscheduled maintenance and repairs. CoolBLUE cores will function throughout the lifetime of the motor without the need for additional maintenance or replacements.

Unlike other common-mode choke methods, CoolBLUE inductive absorbers require minimal installation time. Disconnecting the wiring, installing the cores, and reconnecting the wiring only takes around 10 minutes and provides simple and reliable protection from high-frequency VFD noise. Beyond simple installation time, CoolBLUE limits the potential for costly downtime over the lifetime of the motor by reducing damaging vibrations.

CoolBLUE cores will protect a motor from VFD noise for its full service life with zero maintenance requirements. There are fewer than seven core sizes to fit every motor application, making it easy to select, install, and use for any system. Installing CoolBLUE rings extends the service life of the motor while reducing the cost of maintenance, repair, and replacements. Reduced maintenance and enhanced protection from damaging VFD currents m

CoolBLUE Inductive Absorbers From Renown Electric

With CoolBLUE inductive absorbers, you can protect your electric motor components from unnecessary wear and tear from high-frequency VFD noise. CoolBLUE cores are quick and easy to install, and will last throughout your motor’s service life, thereby reducing maintenance and repair costs. At Renown Electric, we have the knowledge and experience necessary to help you find the perfect absorbers for your system.

To see how CoolBLUE inductive absorbers can improve your electric motor systems, contact our team today.

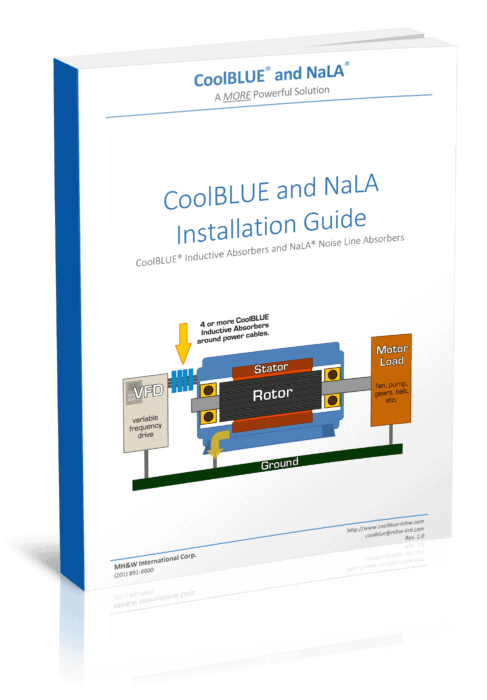

CoolBLUE Design & Installation Guides

Renown offers CoolBLUE Design and Installation Guides so you can better understand how these inductive absorbers deliver the highest reliability and longevity of your motor.

Get in Touch with our Skilled Team

No matter your industry or application, we’re here for you. Contact us to learn more about our extensive capabilities, and how we serve clients across industries to ensure their motors are operating at their best.