A dairy farm recently approached Renown Electric after their new RFID system started failing unexpectedly.

Modern dairy farmers increasingly rely on Radio Frequency Identification (RFID) tags to efficiently manage their herds. Embedded into standard ear tags or worn around the ankle, these tags provide real-time data on a cow’s location, movement, health status (including disease exposure), milking cycles, and milk production parameters—all critical for optimizing yield.

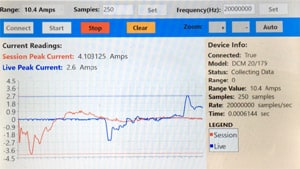

After installing the control computer, readers, and affixing RFID tags to over 400 head of cattle, the system initially worked well. It was only missing one or two cows per milking shift, which was an acceptable range for a new setup. However, the system’s performance soon degraded sharply. Where previously the data loss was minimal, the system was suddenly missing eight or more cows per milking shift. This severe drop in accuracy meant the farmer was losing valuable real-time data on the herd, prompting them to contact Renown Electric to diagnose the sudden failure.

Equipment

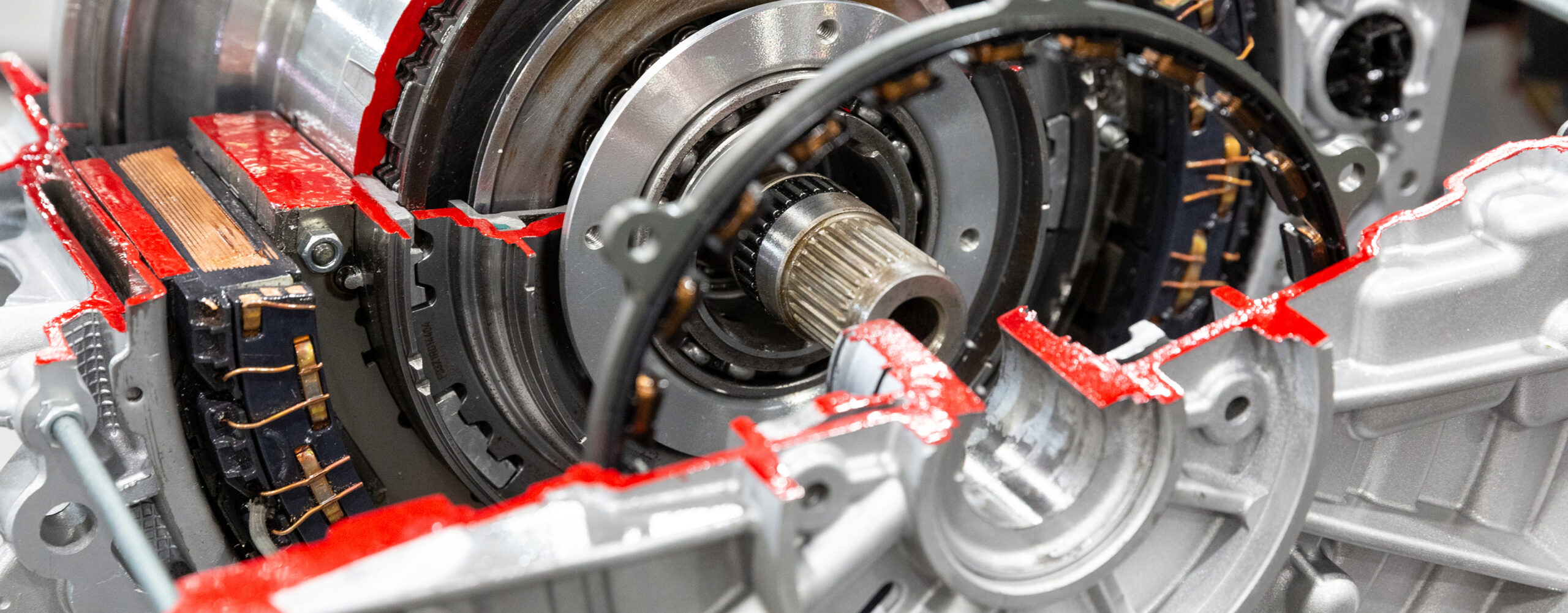

Liquid Manure Aerator with Variable Frequency Drive (VFD)

CoolBLUE Inductive Absorbers (Common Mode Chokes)

RFID Tags, RFID Readers, and Control Computer

Objective

The primary objective was to diagnose and eliminate the source of interference causing the newly installed RFID system to fail, thereby restoring the system’s ability to accurately read and collect critical data from the dairy herd.

Project Duration

Not explicitly stated, but the process involved diagnosis, solution proposal, and installation.

Challenge

A dairy farm with over 400 head of cattle experienced a sudden and significant failure in its RFID tracking system. Initially, the system was performing well, missing only one or two cows per milking shift (an acceptable range). However, performance rapidly degraded, with the system missing eight or more cows per milking shift, resulting in compromised data collection.

Investigation revealed that the failure coincided with the farm’s recent upgrade of its liquid manure aerator, which included the installation of a Variable Frequency Drive (VFD). The VFD, designed to improve energy efficiency, introduced a byproduct: high-frequency currents, specifically common mode current. This electrical noise was interfering with the RFID tags’ frequency, causing them to be missed by the readers.

The Solution

To solve this issue, the Renown Electric team made use of CoolBLUE Inductive Absorbers, a variety of self-contained inductors known as common mode chokes. These absorbers block and absorb, or “choke,” the unwanted frequencies generated by the IGBT or other switches found within variable frequency drives.

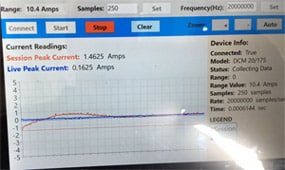

Once installed on the leads from the VFD leading to the aerator motor, the CoolBLUE Inductive Absorbers greatly reduced the electrical noise that was causing the interference affecting the RFID system. The farm’s RFID tag system is now working smoothly and efficiently, missing only one cow per week, rather than eight per milking shift.

Before

After

Process

Renown Electric followed a systematic process to diagnose and resolve the issue:

Investigation and Diagnosis: Visited the farm, inspected the RFID infrastructure, and interviewed the farm team. The key finding was linking the system failure to the recent installation of the VFD on the liquid manure aerator.

Problem Identification: Determined that the VFD was generating common mode current, an electrical noise that was actively disturbing the radio frequencies of the RFID tags.

Solution Deployment: Installed CoolBLUE Inductive Absorbers on the leads connecting the VFD to the aerator motor to mitigate the interference.

Get in Touch with our Skilled Team

No matter your industry or application, we’re here for you. Contact us to learn more about our extensive capabilities, and how we serve clients across industries to ensure their motors are operating at their best.