Secure, Reliable Access to Critical Elevator Shaft Components

Work Safe

- Safe, fast, and reliable access/egress for 1 person!

- Mechanically retained, and electrically interlocked

Home Safe

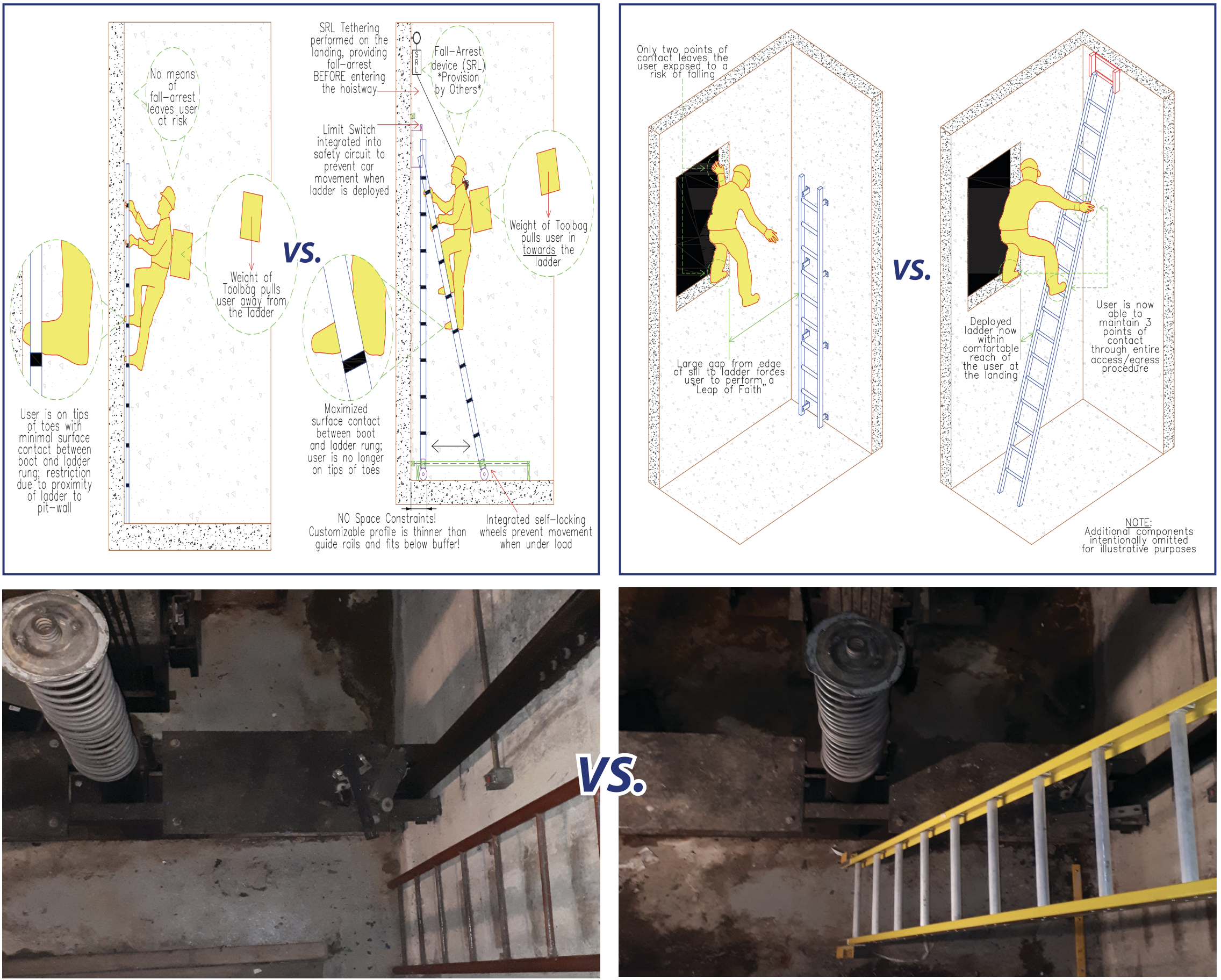

- Fall-Arrest provided before entering the hoistway

- No space constraints, no leap of faith, NO problem!

Our patent-pending retractable ladder system offers a simple, yet effective means of easing safety concerns when it comes to accessing elevator pits. This system has an enhanced level of safety that supersedes current regulatory compliances. Features include (but are not limited to):

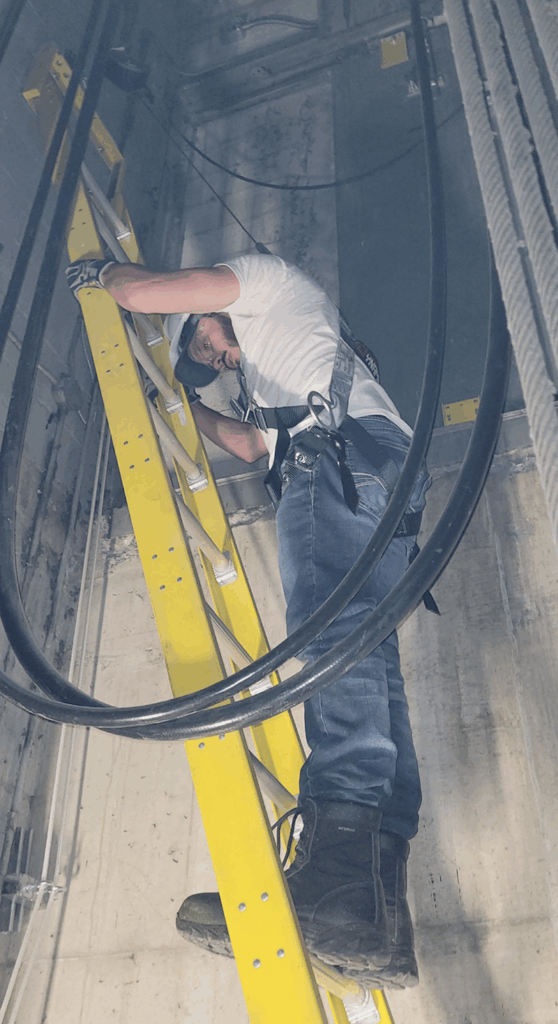

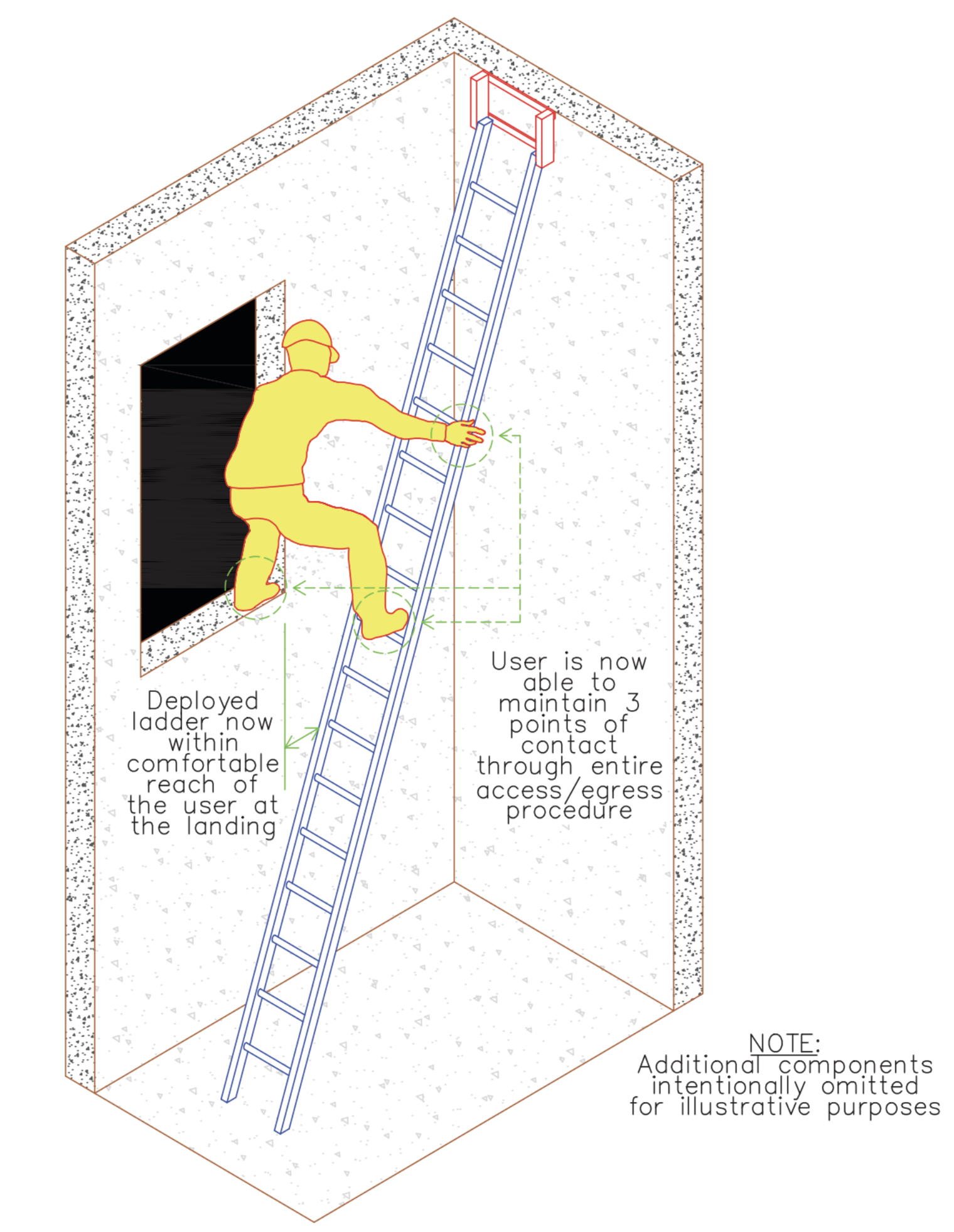

- Allows for 3 points of contact to be maintained at all times from initial access to final egress

- Specially designed rope and pulley deployment/retraction system allows the ladder to meet the user at the landing, thereby eliminating the “leap of faith” factor with less than 9 lbs of applied force required by the user

- Mechanics and inspectors gain significantly faster access to pit – less than 2 minutes are required to safely have boots on the ground in entry or exit; in comparison to several hours for conventional fall-arrest devices to be set up

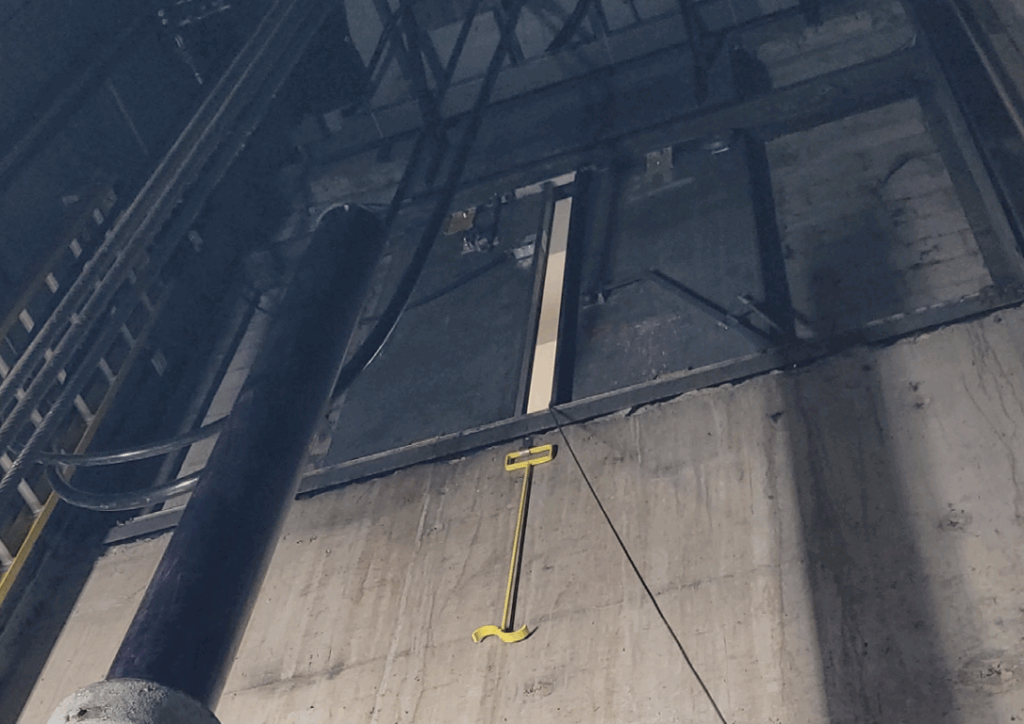

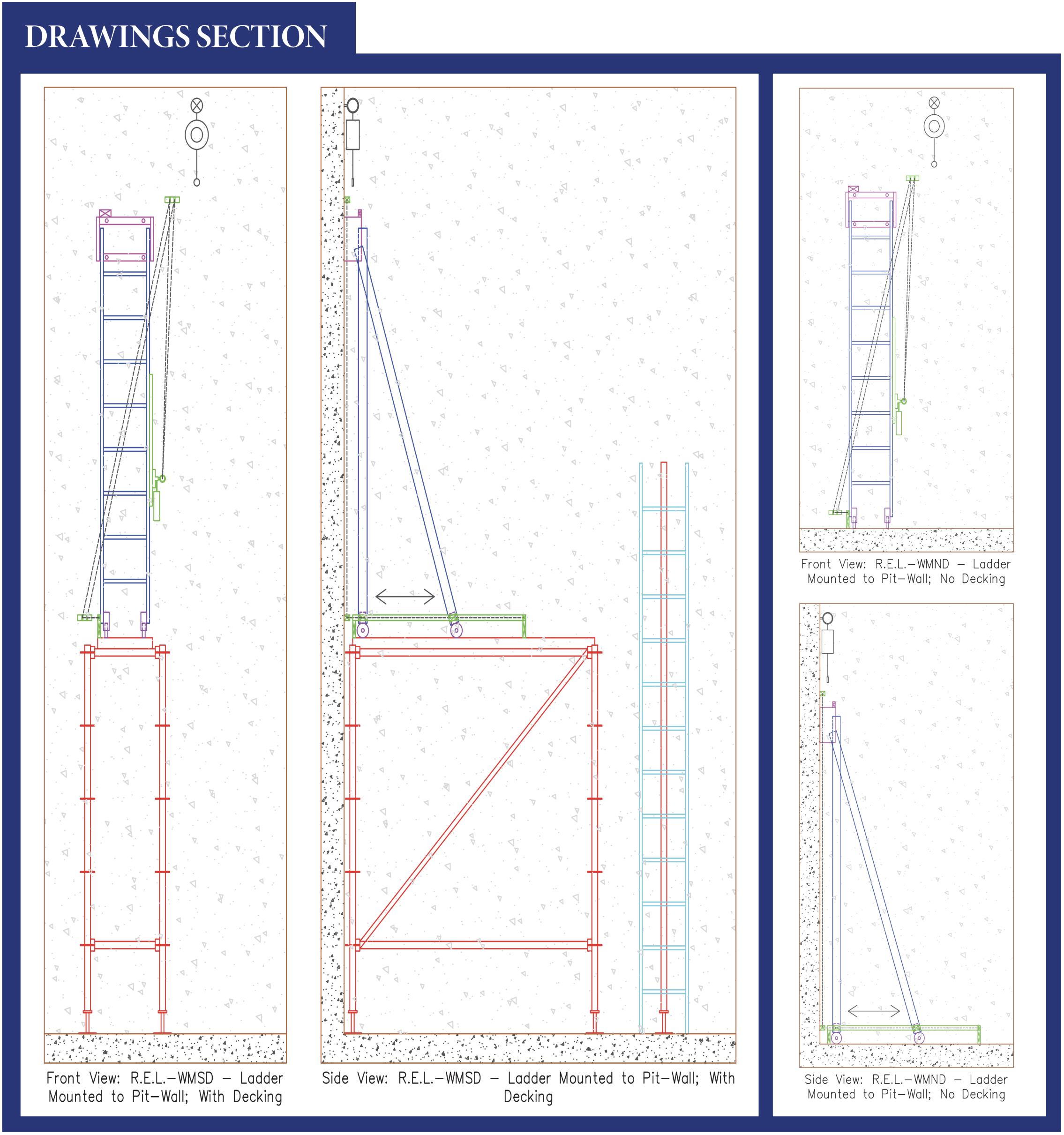

- Provisions made to allow wall-mounting in simplex installations, or trimmer beams in duplex/triplex/quad applications

- Product flexibility allows for integration into any existing or newly constructed hoistway, all profiles, and depths from 4 – 30+ feet

- Normally-open limit switch breaks the elevator safety string once the ladder is deployed and makes it once more when retracted, thus ensuring the elevator is unable to travel in either direction while the ladder is deployed

- Integrated wheel-brake assembly ensures no roll-out when weight is introduced onto the ladder

- Guide rail assembly at the ladder base keeps the wheels captive, thus guaranteeing a true linear operation with no risk of lateral wandering

- Fibreglass ladder rails eliminate risk of electrical conductivity

- 1AA rated ladder means each rung is capable of holding up to 350 pounds

- Non-invasive, timely installation

- Permanent decking stage(s) incorporated to accommodate deeper pits, including a secondary scaffold ladder to access the pit floor from the deck platform

- Minimal maintenance required

- NO impact to customer hall finishes as all tethering points are concealed inside the hoistway

system to be accessed from a safe distance with partial door opening

Existing Solutions vs Proposed Solution

| Renown Part # | Deep Pit Option | Suitable Pit Depth |

|---|---|---|

| R.E.L. – WMHD | Ladder Mtd. @ Wall – No Decking | Up to: 12 ft |

| R.E.L. – WMSD | Ladder Mtd. @ Wall – c/w Single Stage Decking | 13 – 22 ft |

| R.E.L. – WMDD | Ladder Mtd. @ Wall – c/w Double Stage Decking | 23 – 32 ft |

| R.E.L. – TBHD | Ladder Mtd. @ Trimmer Beams – No Decking | Up to: 12 ft |

| R.E.L. – TBSD | Ladder Mtd. @ Trimmer Beams – c/w Single Stage Decking | 13 – 22 ft |

| R.E.L. – TBDD | Ladder Mtd. @ Trimmer Beams – c/w Double Stage Decking | 23 – 32 ft |

Optional Components

- Code-compliant Self-retracting lanyard provides user with an added comfort factor and peace of mind knowing they are tethered in the event of a mis-step

- Anchoring points compatible with poured concrete slab, as well as steel or concrete trimmer beams

Work with Speed and Safety in mind.

Our solutions help building owners and contractors meet safety codes and standards, enhance overall job-site safety, and contribute to the long-term reliability and serviceability of the elevator system.

Cost Savings on Preventative Elevator Motor Maintenance

Repair and maintenance costs represent the second-highest expenditures within the average business.

Get in Touch with our Skilled Team

No matter your industry or application, we’re here for you. Contact us to learn more about our extensive capabilities, and how we serve clients across industries to ensure their motors are operating at their best.