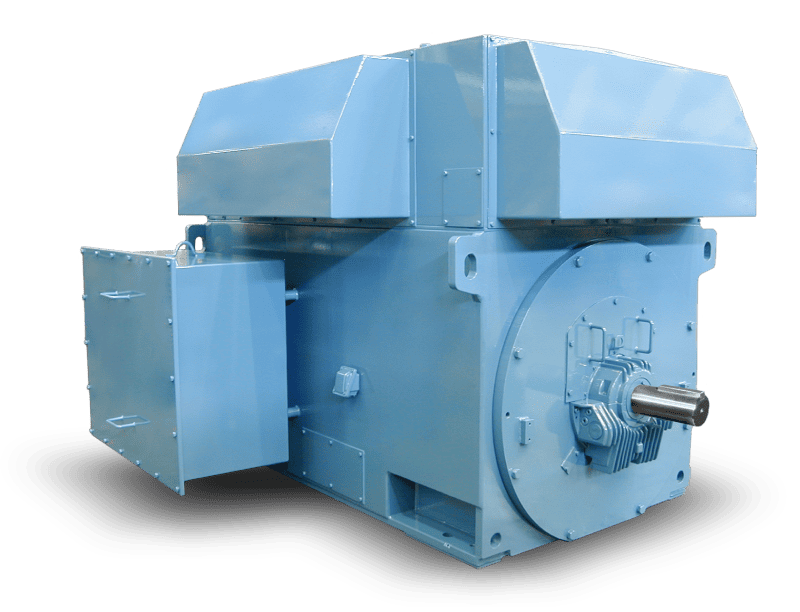

The National Electrical Manufacturers Association, or NEMA, is a trade association that sets industry standards for a range of electrical components, equipment, and medical technologies, including electrical motors. When motors are larger than the frame sizes outlined by NEMA, they are referred to as Above-NEMA, or A-NEMA, motors. In this blog, we’ll provide an overview of A-NEMA motors and the key factors to consider when selecting the right A-NEMA motor for your application.

What Are Above-Nema (A-NEMA) Motors?

North American manufacturers of electric motors must follow NEMA guidelines when it comes to frames, efficiency, and production. However, the rest of the world complies with International Electrotechnical Commission (IEC) standards, which are the European-based equivalent to NEMA guidelines for electric component and motor manufacturing.

A manufacturer that complies with IEC standards can choose from a more extensive variety of products throughout the global market. This allows companies to boost their flexibility, reduce production costs, and diversify their supply chains. IEC standards also focus on energy efficiency and sustainability in compliance with European and global regulations, making the rating more favorable in international markets where energy efficiency is a priority.

An electric motor that is Above-NEMA (A-NEMA) is not unregulated; rather, it is a custom-engineered size. These motors follow many of the same standards as regularly sized motors; however, they are specifically manufactured for larger rotating electrical machines that range from hundreds to tens of thousands of horsepower. These motors are engineered to meet certain specifications for:

- Voltage

- Mounting type or requirements

- Hazardous area classification

- Frame size

- Documentation

- Design aspects

Do Standardized Frame Sizes Exist for A-NEMA Motors?

A-NEMA motors have standardized frame sizes ranging from 440T to 1000L. The frame sizes for A-NEMA motors can differ depending on the manufacturer; however, there are still standard frame sizes that are popular throughout the industry.

Considerations When Selecting A-NEMA Motors

The following considerations are vital to selecting the right A-NEMA motor:

- Application requirements. It’s crucial to consider your application’s requirements for power output, speed, duty cycle, torque, and environmental conditions. This will ensure the A-NEMA motor you select will perform reliably and efficiently for the intended use.

- Physical dimensions. A-NEMA motors come in a wide range of standard and non-standard shapes and sizes. As such, it’s important to choose an A-NEMA motor that will fit properly within the available space and mounting configuration. The size of the motor’s frame is especially important to consider in this regard.

- Operating efficiency. A-NEMA motor efficiency can vary widely, so it’s critical to choose a motor that meets or exceeds the standards set by regulatory agencies regarding efficiency levels. Doing so will reduce costs associated with operations and energy usage over your motor’s lifespan.

- Motor options and features. A-NEMA motors come with various options and features, including vibration monitoring, numerous types of enclosures, and high-speed bearings. Be sure to consider which of these options your application requires and choose an A-NEMA motor that fits those criteria.

- The reputation of the manufacturer or supplier. Choosing a reputable supplier or manufacturer is paramount in ensuring the quality of your A-NEMA motor. These companies will also be able to support your motor over its lifetime to ensure you don’t experience costly downtime. When looking for the right manufacturer or supplier, consider their service capabilities, product warranties, and technical support.

Power Up Your Applications With the Right A-NEMA Motor

Although North American manufacturers must comply with NEMA standards for motor frames and production, other applications may require larger A-NEMA or non-NEMA motors. At Renown Electric, we’re a distributor of non-NEMA motors, including those that are compliant with IEC standards. In addition to our wide selection of IEC motors, we also offer predictive maintenance programs that include balancing, infrared thermography, vibration analysis, and more to keep your motors in optimal condition.

For more information about our non-NEMA motors, or for help selecting the right motor for your application, contact the experts at Renown Electric today.