Blog

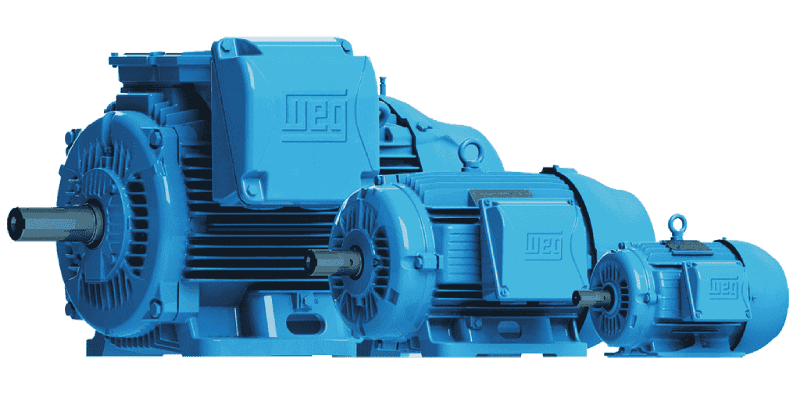

Almost any industrial activity depends on an electric motor. When repair vs. replace considerations arise, the choice can result in thousands of dollars saved or lost. This is partly due to the direct repair/replacement costs but also as a result of downtime that grinds operations to a halt. Making the right call between electric motor replacement vs. repair is thus extremely vital to minimizing downtime and costs.

Should You Repair or Replace Your Electric Motor?

It’s essential to make time for regular servicing appointments. Preventative maintenance is the most reliable way to keep long-term equipment costs low, as poorly serviced electric motors are a common cause of motor repair and replacement issues. Consider these factors when deciding whether to replace or repair your electric motor:

- Environmental impact: Repairing motors results in less waste by extending the lifespan of existing equipment while reducing demand for new motor manufacturing. It can also help operations meet financial and waste-reduction goals.

- Lead time: Compare the lead time for repair and replacement. Generally, repairs have a shorter lead time than new motors, which tend to take longer to order, ship, and install in your facility.

- Extent of damage or wear: If the severity of a motor’s damage is extensive, repairs may be more costly than replacement. Worn brushes, bearings, or capacitors can be cost-efficiently repaired, while major damage to windings or other essential parts could be beyond repair.

- Cost of repair vs. replacement: Generally, if electric motor repair costs reach 50% to 75% of the cost of replacement, it may be a better idea to replace the motor.

- Motor age: At some point, motors reach the end of their expected lifespan, where repairs occur more frequently and the one-time cost of replacement is justified. If the motor is relatively new and the cost of repair is reasonable, repair is the better choice.

- Parts availability: Waiting on parts for outdated motors or uncommon brands can create costly downtime. Replacement parts can even become difficult or impossible to find and result in extensive custom repair work.

- Energy efficiency: New electric motors are often more energy efficient, resulting in greater long-term energy and cost savings.

- Performance requirements: Determine whether the motor, once repaired, would meet the output and efficiency requirements of your operation. If not, you may need to replace it.

- Downtime and lost productivity: Assess the financial impact of motor downtime in your production. Perhaps the downtime is expensive, and it’s more financially feasible to do a quick replacement rather than an extensive repair.

- Service history: On reviewing a motor’s maintenance history, look for signs of recurring issues. This could make a replacement electric motor the smarter option.

- Technological upgrades: Replacing your motor with a newer model may be worth the higher cost if you need the enhanced features.

- Warranty coverage: See if your electric motor is still under warranty because this alone can significantly cut your repair costs.

- Expert opinion: Motor technicians and engineers can provide a reliable assessment of the motor’s true condition and then suggest the most effective solution.

A cost-benefit analysis using the points above will help determine whether industrial electric motor repair or replacement is the wisest course of action. Compare each choice’s short- and long-term benefits and decide what your cost threshold is where repair is no longer cost-effective.

Premium In-House Motor Repair Services from Renown Electric Motor

Renown Electric’s extensive in-house motor repair services help our customers extend the service life of their motors. Our 60,000 sq. ft. repair facility in Concord, Ontario, has everything needed for full motor repair and diagnostics, including:

- Motor rewinding and rebuild

- Gearbox rewinding and rebuild

- Generator rewinding and rebuild

- Sheave regrooving and manufacturing

- Servo motor repair

- Machine shop services

- Motor drive repair

- Pump repair

Our Preventative & Predictive Maintenance Services

Regular electric motor service will keep your motor’s repair costs low. Our comprehensive preventative maintenance program includes:

- Dynamic balancing

- Laser alignment

- Infrared thermography

- Vibration analysis

- Motion amplification

- Winding analysis

- Oil analysis

Quality You Can Trust

Renown Electric Motors & Repair Inc. is committed to providing our customers with the best quality of services and products—that’s why we work hard to maintain our many certifications:

- ISO 9001:2015

- Electro-Mechanical Authority (EASA) Member

- Electrical Safety Authority (ESA) Member

- Canadian Standards Association (CSA) Qualified for the Repair and Service of Motors and Generators in Hazardous Locations

- ISN-Compliant

- EXIROS-Compliant

- QUAREM-Compliant

- ISNetworld

- Cognibox

- Avetta

- Contractor Compliance

- Contractor Check

Contact Our Electric Motor Repair and Service Experts

Deciding between motor repair vs. replacement can be a challenge, especially considering expenses from both the repair/replacement and downtime. Conduct a cost-benefit analysis of all relevant considerations, or have an expert team like Renown Electric help you decide which course of action is best for your motor and facility.

In addition to in-house repairs, we also provide a range of on-site field services for customers across Canada. With decades of experience and industry-leading certifications, Renown Electric is prepared to help you with even the most challenging motor needs. Contact us today to begin your solution.

Comments are closed