Rotors are essential components in electric motor operation. Keeping them properly balanced by addressing any issues in electromechanical systems helps ensure motor longevity and optimal performance. Learn more about why rotor balancing is important, how electrical and mechanical conditions play into a rotor’s alignment, and how preventative and predictive rotor maintenance can help you protect your equipment.

Importance of Rotor Balancing in Motors

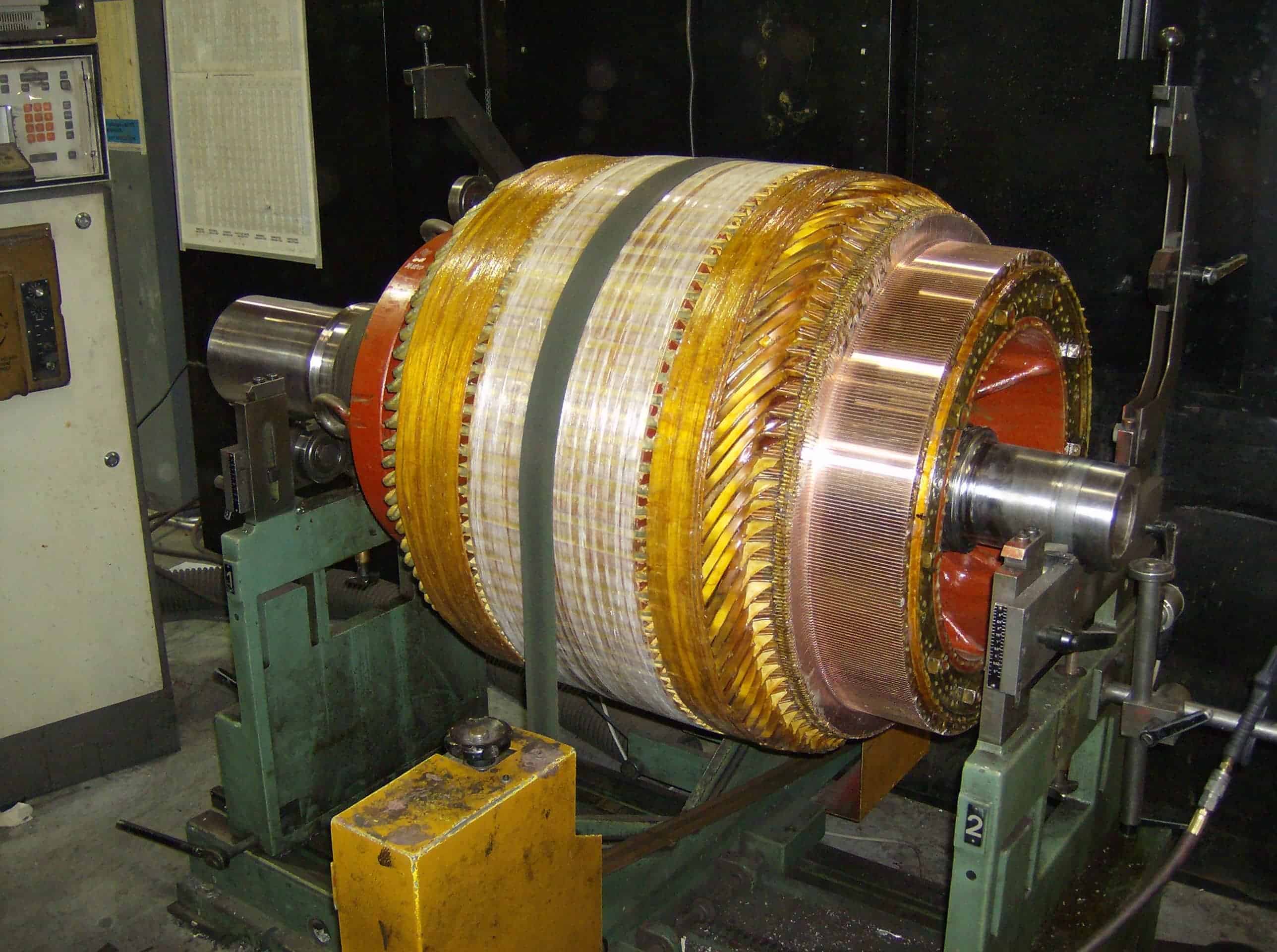

Rotors in electric motors generate rotational motion from electrical or electromagnetic energy. During operations, an imbalance can occur when more weight is applied to one side of the rotor than the other. Rotor balancing is necessary to ensure that the weight distribution on a rotor is even for optimal axis alignment, enhancing the reliability and efficiency of a motor while protecting critical components like seals and bearings. Imbalance can start off as increased vibration or noise. If left unaddressed, however, electrical imbalances and mechanical problems can result in premature failure of the motor.

Role of Electrical & Mechanical Elements in Rotor Balancing

Successfully balancing a rotor requires you to evaluate and address both mechanical and electrical factors. Failing to consider the electrical components within rotating equipment ignores the effect that electrical imbalance and other irregularities can have on mechanical components. The following are examples of the interconnected role that electrical and mechanical factors play in rotor balance:

- Force generation. Voltage imbalance, uneven winding, and other such electrical problems will distribute force unevenly on a rotor, resulting in rotor imbalance and preventing smooth rotational movement.

- Vibration induction. As machinery operates, electrical problems can lead to imbalance and then vibration for reduced rotor performance. These vibrations can then increase a rotor’s mechanical imbalance, negatively impacting the system’s stability.

- Dynamic interactions. These interactions between mechanical and electrical parts take place during rotation and can cause mechanical instability. They also worsen problems with electrical balance and vibration in a rotor.

- Winding integrity. Imbalanced rotors promote vibrations in electro-mechanical systems, degrading stator winding integrity. Winding analysis is a critical method for evaluating such electrical conditions and their effect on rotor balancing.

Avoid Rotor Imbalance With Premium Preventative & Predictive Services From Renown Electric

At Renown Electric Motors & Repair Inc., we’re here to assist with your rotor balancing concerns. We offer various preventative and predictive maintenance services for electric motors, including vibration analysis, winding analysis, and dynamic balancing, to provide you with comprehensive equipment care solutions.

Vibration and winding analyses work together to assess the health of electric motors and generators. Vibration analysis diagnoses the equipment’s mechanical condition, looking for imbalance and misalignment as well as mechanical looseness, and winding analysis examines for electrical concerns like degrading insulation and the ingress of moisture or contamination. When vibration analysis detects imbalances, dynamic balancing as a preventative maintenance strategy fixes imbalances to improve equipment reliability and reduce wear and tear.

Renown Electric combines these services to promote holistic motor and generator health through proactive monitoring and maintenance. We leverage our expertise with state-of-the-art equipment like the VIBXPERT II balancing system, a Baker D65R, an Advanced Winding Analyzer (AWA-IV), and i-Alert® sensors to evaluate your motor and its components for optimal efficiency and reliability. Our team can provide rotor balancing and related maintenance services in-house and in the field.

As evidence of our commitment to quality in both products and services, Renown Electric also maintains the following certifications:

- Avetta

- Canadian Standards Association (CSA)

- Cognibox

- Contractor Check

- Contractor Compliance

- Electrical Safety Authority (ESA)

- Electro-Mechanical Authority (EASA)

- EXIROS

- ISNetworld

- ISO 9001:2015

- QUAREM

We combine our extensive knowledge, well-equipped facilities, and certified processes to drive efficiency and help you reach your operational goals.

Contact Our Experts for Premium Rotor Balancing Services

Rotor balancing services are critical to the electrical and mechanical health of your equipment. The expert team at Renown Electric is backed by nearly 40 years of experience in supplying and repairing high-performance electric motors and generators, enabling us to deliver premium rotor balancing solutions and quality services to clients worldwide. Contact us today to learn more about our capabilities or speak with an expert about your rotor balancing needs.