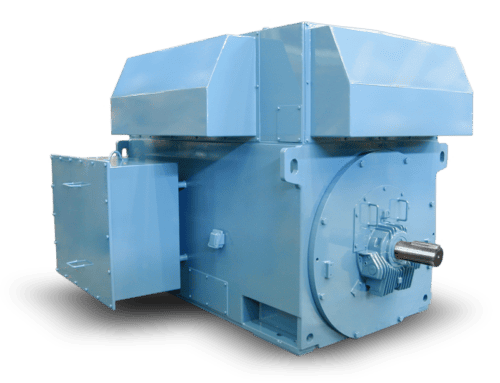

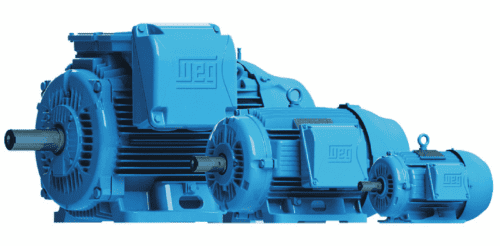

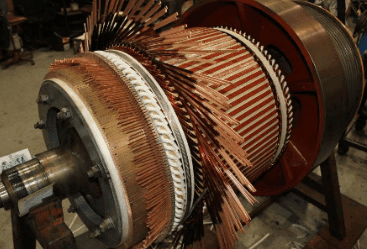

Electric Motor Repair vs. Replace – Costs, Benefits

Almost any industrial activity depends on an electric motor. When repair vs. replace considerations arise, the choice can result in thousands of dollars saved or lost. This is partly due to the direct repair/replacement costs but also as a result of downtime that grinds operations to a halt. Making the right call between electric motor […]

Read More… from Electric Motor Repair vs. Replace – Costs, Benefits