Variable frequency drives (VFDs) have changed the way we use electric motors and electric motor-driven equipment. With the ability to match demand loads and increase operating efficiency and output, these versatile tools allow for reduced electricity use as well as reduced costs.

However, electrical noise — such as the shaft voltages and bearing currents that may be generated from the common mode output of these drives — can cause unwanted arcing. This, in turn, can result in a huge range of issues; audible noise, frosting, bearing fluting, lubrication breakdown, and even eventual motor failure can all result from ineffectively managed drives.

Managing Current Paths in Variable Frequency Drives

Electrical current will always seek the easiest, most direct path to travel, which means it will impact the more vulnerable parts of a motor, causing disruption to overall operations. While the current is simply behaving in accordance with its nature, managing it can be challenging, since it directly affects the lifespan of the motor.

VFDs are designed for high performance and efficient operations, but unwanted frequencies are inevitable. The drive produces excess electrical currents that manifest themselves in a variety of ways throughout a system; common mode noise and currents, bearing currents, and shaft voltages are all common issues, which demand grounding, filtering, or other direct forms of management or absorption to properly remedy.

And because they are generated by the VFD itself, these unwanted currents have an easy path to the motor. They can travel straight down the leads that connect a VFD system, heading directly into the motor and its bearings.

Common Mode Chokes and Shaft Grounding Rings

Without a “choke,” or filter, of some kind, disruptive electrical noise can cause lasting system damage. Insulation and insulated bearings, engineering of alternate discharge paths, Faraday shields, grounding brushes, shaft grounding rings, ceramic bearings, and shielded cables can all help to manage the problem, depending on the specific application.

Each offering its own unique benefits, these components manage and direct currents in various ways. Below are a few of the most popular solutions.

Insulated Bearings — Insulated and ceramic bearings create a high-impedance ground path for unwanted currents. This prevents electrically induced bearing damage, as well as motor damage. However, these bearings offer no guarantee that ground current won’t seek out another damaging path through the motor; they don’t eliminate shaft voltage, they simply block one of its easiest routes.

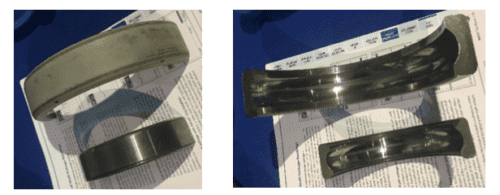

Insulated Bearing on top, regular bearing on bottom both with evidence of current running through bearings.

Grounding Brushes — These components provide an alternate low-impedance path between a motor shaft and motor case, channeling current away so that it can’t build up on the rotor. While grounding brushes can be highly effective tools, they can also be difficult to retrofit on to existing applications, costly and difficult to maintain.

Grounding Rings — Carbon brushes made of conductive micro-fibers inserted directly onto the shaft, these rings create a direct connection to the motor frame. This also creates a low-impedance ground path to channel noise, minimizing wear on bearings however have issues with maintainability and application specific environment issues.

Common Mode Chokes — Common mode chokes, such as CoolBLUE Inductive Absorbers, are self-contained electrical inductors. These block and absorb the electromagnetic interference and unwanted noise, while still allowing differential currents to pass through and power the motor. These components don’t create any new paths; they simple buffer the problem currents and eliminate them.

Optimizing Your System Potential with Renown Electric

For over three decades, the team at Renown Electric has been providing industry-leading electric motors, parts, and repair services for various industries, from automotive and marine to wastewater and mining.

We understand the devastating effects of electric motor and common mode noise, and are proud to offer CoolBLUE Inductive Absorbers from MH&W International Corp. Versatile and high-performing, these absorbers help to reduce bearing damage due to electrical discharge and extend system life in a huge range of applications, including multiconductors, industrial HVAC, automotive manufacturing, hospitals, and commercial buildings.

We recently installed CoolBLUE absorbers in a VFD on a liquid manure aerator at a dairy farm. This helped manage the common mode current and, in turn, restored efficiency to the operation’s malfunctioning RFID system.

All types of electric motor applications are prone to unwanted frequencies and disruptive currents, and the Renown team is ready to help. Strategic, high-performing common mode chokes like the CoolBLUE system can do more than just enhance the immediate efficiency of your operation; their high-frequency noise protection also allows for maximum equipment reliability, minimized maintenance needs, and reduced downtime.

Learn More

To learn more about how to protect your motor’s lifetime and performance, download our free eBook, “Avoiding Motor Shaft Voltage & Bearing Current Damage,” or reach out to an expert today to discuss your company’s specific needs.