To measure the health of an electric motor, engineers must consider several key factors, including performance, energy use, operating costs, equipment durability, and overall system reliability. These are all integral components of motor health, which depends on regular monitoring and diagnostic testing. When evaluating the health of a motor, the following aspects should be carefully analyzed: alignment, ventilation, lubrication, consistency of operation, and heat output.

But when actually conducting motor troubleshooting, it can be tricky to locate the exact source of the problem, whether it’s an issue with the power supply, branch circuit conductors, motor controller, or load. Proper testing, therefore, is a crucial step in motor upkeep. Below are a couple of the most common motor tests available, which can allow for significant time and cost savings — thereby reducing the need for maintenance, repairs, and extra labor.

Primary Analysis

To pinpoint specific motor issues, a range of diagnostic tools are available, such as clamp-on ammeters, temperature sensors, megohmmeters (or simply meggers, used for Megger tests), winding analyzers, and oscilloscopes. Your six senses, however, are often the best indicators of potential trouble. For instance, the motor might be overheating or emitting strange sounds and smells; use these obvious issues as starting points. And when evaluating your motor, start with the basic measures of motor performance such as current levels, power, voltage, and resistance. You should also employ a multimeter, a versatile tool for preliminary testing.

Motor Testing Methods: Isolating the Problem

Electrical motors are utilized in seemingly infinite applications, from small electric fans to large-scale manufacturing and industrial equipment; motors are crucial for carrying out everyday work in facilities across the country and around the globe. This is why motor failure is such a serious issue; the resultant costs, downtime, and general disruption can be disastrous to overall facility operations. But dedicating time to thorough motor testing can reliably prevent unscheduled downtime and unanticipated maintenance costs, keeping processes running smoothly and efficiently.

The Hipot Test for Dielectric Strength

Hipot testing, or dielectric strength testing, tests insulation using a high-voltage source. This test is useful for both AC and DC power and applies a continually changing voltage to a cable. The voltage alternates from positive to negative and runs for 50 to 60 full cycles to measure the total current flow. Hipot insulation resistance testing illuminates the causes of current flow issues and can indicate underperforming insulation. This test is also useful for isolating and identifying arc problems.

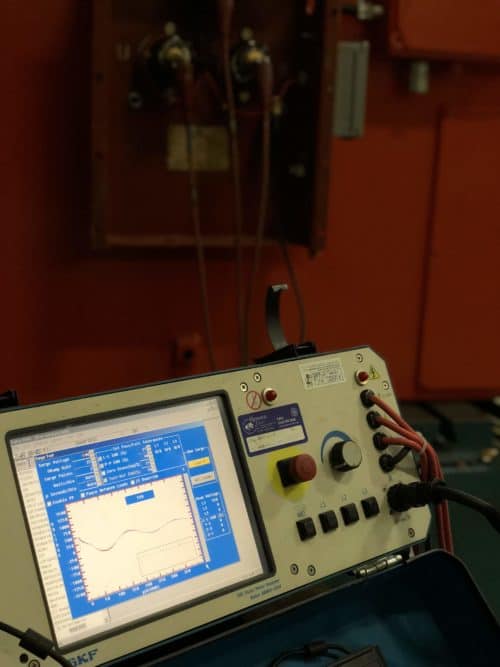

The Surge Test for Isolating and Detecting Burnout

Surge testing is one of the most reliable methods of motor burnout detection, as the test can reliably predict future motor failure. Surge testing identifies shorted motor conductor turns and failing conductor insulation, both of which are early warning signs of electrical breakdown. Insulation on a motor’s windings may erode as a result of chemical deposits, manufacturing or rewinding errors, routine startup movement, or heavy use. This insulation resistance test requires a specific type of machine to show the performance of individual sets of motors, allowing users to analyze each set’s performance and compare it to the others.

Learn More

There are several tests available for evaluating the health of an electric motor and better understand its condition and future maintenance needs. Depending on the specific application and issue, Megger testing, voltage drop testing, and core loss testing, among others, can be critical for ensuring optimal motor functioning and longevity.

To learn about the other tests Renown Electric conducts on electrical motors, download our new eBook, “The Basics of Motor Testing.”