How Winding Analysis Keeps Motors Running within a Predictive Maintenance Program

This post is the third in a monthly series of “How It Works” articles that detail the inner workings of motor maintenance services and processes.

The failure of a large motor can be deeply disruptive to the rest of a facility’s operations. Our monthly series in understanding how your motor works — and the preventative and predictive maintenance services and processes that can make it work better — is why we’re here.

In our third post of this series, we’ll be investigating winding analysis. Along with dynamic balancing, laser alignment, infrared thermography, oil analysis and vibration analysis, winding analysis is a basic maintenance operation that can enhance motor life and decrease energy consumption.

Evaluating Motor Lifespan

Preventative maintenance on an electric motor relies on two types of analysis:

- First, evaluating the remaining lifespan of the equipment’s insulation and operating system.

- Second, evaluating the operating conditions that will add strain or workload. These can include environment, load, cycling variation, and other external factors that impact performance.

By assessing when and how a motor can be affected, it’s easier to detect and resolve potential motor issues before they actively occur, allowing maintenance to be carried out effectively — and preemptively — during scheduled shutdowns. This avoids costly failures, unscheduled maintenance, and premature issues in equipment.

Motor Winding Analysis Tests and Tools

A form of non-destructive testing, motor winding analysis can be applied not only to motors, but to transformer and generator windings as well. Along with Motor Current Analysis, this testing is used specifically to classify electric winding insulation, but the information it provides is significantly more sophisticated.

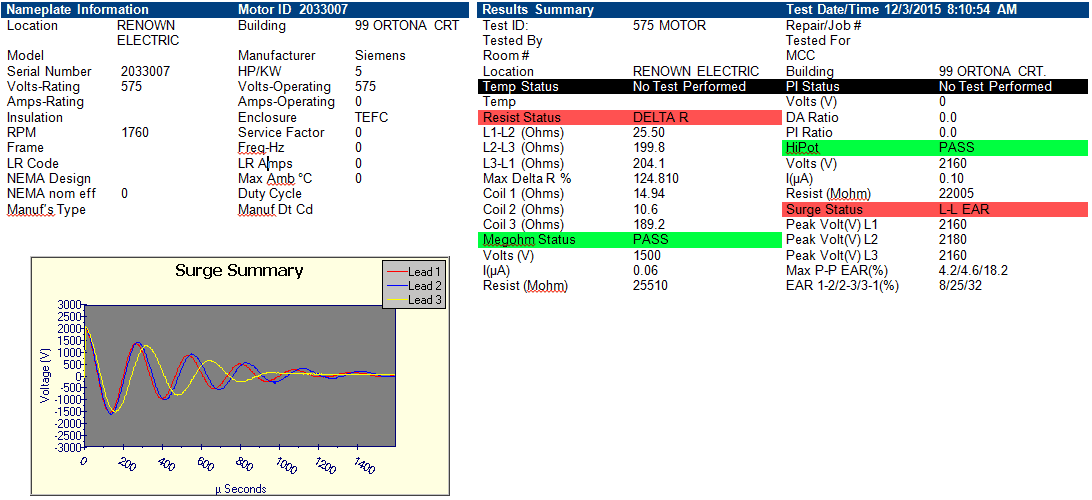

Example of a Failed Winding Analysis Report:

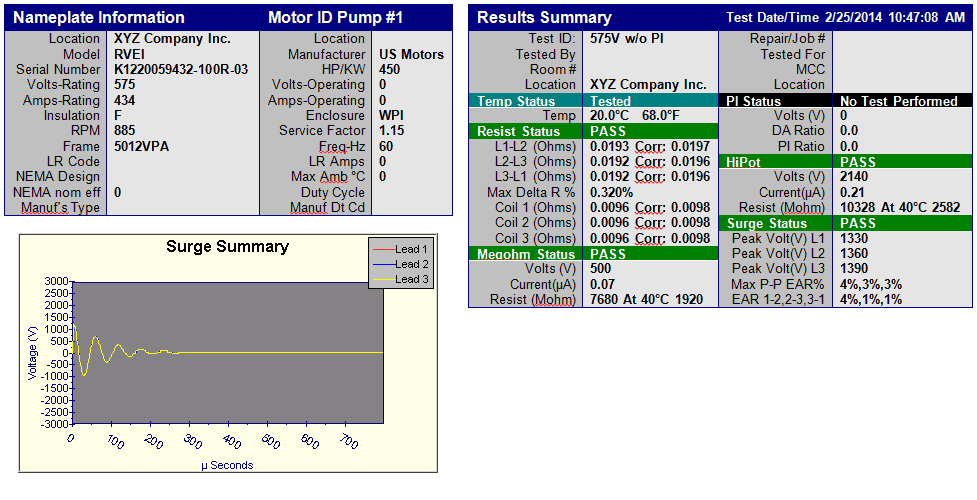

Example of a Successful Winding Analysis Report

Many problems that indicate premature failure of motor components can be revealed through the information collected through Motor Winding Analysis. Helping to detect and eliminate winding issues and their subsequent related problems, as well as monitoring the dielectric strength of winding insulation, is critical in preventing overall failure and determining the urgency of repair needs.

Two types of testing constitute a full motor winding analysis. They are:

- Off-line Testing: Including phase to phase resistance test, Surge Test, Hipot Test, and 1-Minute Megger Test

- On-line Testing: Evaluating and measuring the amps and voltage per phase when a motor is running, as well as Rotor Bar tests

These tests can be conducted with the help of an Advanced Winding Analyzer (AWA-IV) and a Baker D65R, depending upon motor type.

Winding analysis can also be utilized as a powerful troubleshooting tool. Many facilities utilize a hand held megger to test the insulation strength. This is an effective method for detecting ground faults. However, internal shorts within the windings may not appear as a ground fault. As a result these faults may be missed during troubleshooting costing valuable down time. A winding analysis test will detect even slight resistance unbalance between phases and the surge test will quickly detect internal shorts within the windings.

GLOSSARY OF TERMS

Surge Test: Used to test a variety of inter-winding faults that DC tests will not normally detect.

Surge Comparison Test: A comparison of two individual Surge Test wave patterns from separate windings to see if they differ. Two methods of comparing wave patterns are Error Ratio (E.A.R.), or Zero Crossing Tolerance. When the wave patterns are the same, there is no short in either winding. When the wave patterns differ, one of the windings contains a short.

Surge Waveform (Surge Data): The resulting data from a surge test. It can be viewed graphically on the View Waveforms screen.

Megohm Test: A low-voltage test used to measure the insulation resistance of a winding in megaohms. In Automatic Test Mode, for motors rated less than 600 volts, the test voltage will be 500 volts.

For motors rated more than 600 volts, the test voltage will be one-third that of the default test voltage table.

Polarization Index: A ratio between measured insulation resistance values taken at one minute and ten minutes. It is obtained from data that is collected every two seconds. Note: The PI test is useful for testing complex insulation systems, such as large motors and generators, where repeatable measurements are difficult to obtain.

“Hipot” Trip Fault Detection: Built-in circuitry that will stop any test when it detects Hipot current levels that are higher than a predetermined safety limit. After a Hipot Trip, a message will appear on the screen and “Trip” will be entered into the motor data form. The test will be considered “failed.” It will set to 600u amps when the Analyzer Hipot test is set to 100ua/div and 60 u amps when using the 10 or 1 u amps setting.

“Hipot” is short for high potential (high voltage). A hipot test checks for “good isolation.” Hipot tests are conducted to ensure no current will flow from one point to another point. In some ways a hipot test is the opposite of a continuity test.

Continuity Test: Ensures current flows easily from one point to another point.

Hipot Test: Ensure current will not flow from one point to another point.

The team at Renown Electric provides these services both in the shop and on the road, along with a host of additional maintenance services to keep your systems running smoothly. To view a sample of a real winding analysis report, access the report from our resource library.