5 Motor Testing Methods You Should Be Implementing With Your Electric Motor Test Design

To have an efficient electric motor running means more than just adequate performance; energy efficiency, operating cost, life span, and system reliability are all interconnected with overall motor health. To keep these variables in check, regular motor testing and monitoring are critical. Even basic diagnostic testing can allow for major cost and time savings, reducing the need for maintenance, repairs, and overall labor needs.

Various elements, including alignment, ventilation, vibration, and lubrication levels, can impact the health of your electric motor. So when a motor fails to start, runs intermittently, produces large amounts of heat, routinely trips its safeties, or operates unreliably, it’s key to isolate the underlying cause of the problem by evaluating basic system levels and conditions.

Sometimes motor trouble originates from the power supply, branch circuit conductors, or motor controller. Sometimes the load is jammed, binding, or mismatched. Sometimes the motor itself has developed a fault — a burnt wire, a broken or bad connection, a winding failure, or a deterioration in critical insulation or bearings.

Troubleshooting and monitoring these elements before diving straight into repair can go a long way in reducing costs, labor needs, and downtime, while also providing better security against future failure, since you’ll be better equipped with the necessary information to plan efficient maintenance and upkeep.

Basic Motor Testing Parameters and Tools: Primary Analysis

There’s a huge range of diagnostic tools available for pinpointing motor issues — clamp-on ammeters, temperature sensors, Meggers, winding analyzers and oscilloscopes, just to name a few. And depending on the specific area of trouble, each tool can help illuminate the problem in different ways.

A good rule of thumb for troubleshooting a motor is to first rely on your senses: Is the motor hot or overheating? Does it smell or sound unusual? Is it physically behaving in an erratic way? To begin an evaluation, check in first on the basic measures of motor performance: current levels, power, voltage, and resistance.

Preliminary tests are generally done using the ubiquitous multimeter, which can provide diagnostic information for all kinds of motors.

Motor Testing Methods: Isolating the Problem

Complex, powerful tools, electric motors are critical components in a wide range of equipment and tools, from the smallest electronic fans to the largest manufacturing and industrial equipment. Without motors, many basic industrial functions would be severely compromised, if not impossible; motors are the heartbeat of daily work.

Motor failure, therefore, can be extremely costly and disruptive, resulting in unscheduled downtime and unplanned maintenance costs. But by dedicating time to thorough motor testing — both in regular, routine maintenance programs and at the first sign of trouble — motor issues can be reliably predicted, prevented, isolated, and resolved with minimal service disruption.

Below are just a few of the many motor tests available.

1. The Hipot Test for Dielectric Strength: Determining Efficacy of Cable Insulation

Performed as a detection of weakness and potential for failure within cable or wire insulation, high potential (hipot) testing, also known as dielectric strength testing, should be performed after conducting initial visual inspection and insulation resistance tests.

Using either AC or DC voltage, the hipot test involves applying current between electrical circuits and the frame. Overvoltage levels applied during this test are unique to each machine and its specified voltage. When assessing the strength of new windings, the standard test is run by continuously applying 1,000 volts, 50-60 Hz, plus two times the specific machine voltage rating for 60 seconds.

Hipot testing should only be conducted once at full strength and subsequently at 85% strength on additional tests so as to avoid overstressing the insulation under assessment. In cases of reconditioned insulation, the test should be run at 60% of normal test voltage to avoid overloading the material.

2. The Surge Test: Isolating Shorts and Detecting Burnout

A critical part of comprehensive, routine motor maintenance, surge testing can reliably detect motor burnout and offers assistance in predicting future motor failure.

Surge testing allows for the identification of shorted motor conductor turns and failing conductor insulation, which are among the first telltale signs of electrical breakdown. Chemical deposits, manufacturing or rewinding errors, routine startup movement, and heavy use can all wear away insulation on a motor’s windings.

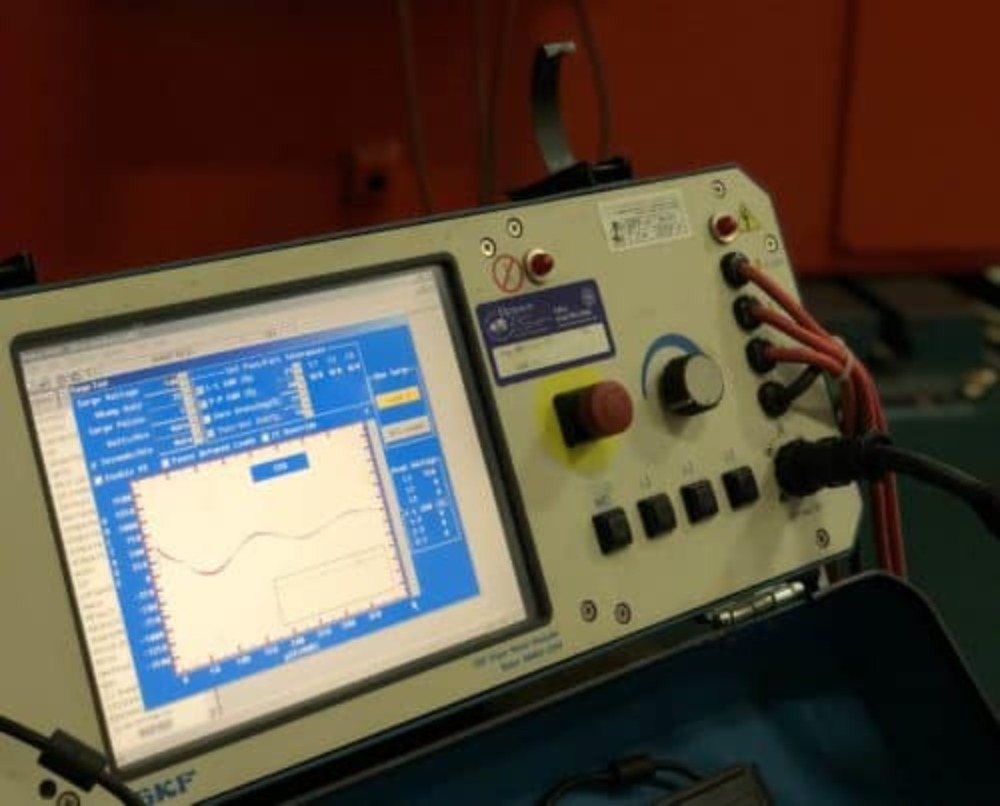

With the use of a Baker or Electrom-type testing machine, technicians and maintenance professionals can safely apply a voltage pulse — or surge — to every set of motor windings in order to isolate their performance both individually and in comparison to one another.

The standards for surge testing are defined by IEEE 522, which set appropriate voltage levels for a wide range of winding types and conditions.

3. The Megger Test: Evaluating Critical Insulation Performance

The megohmmeter (or “Megger” by its trade name) insulation resistance tester allows for reliable, periodic testing of the overall insulation performance of tools, appliances, motors, on-the-reel cable, capacitors, power distributions subsystems, and essentially any kind of electrical equipment or high-performance wiring.

The Megger test applies a high voltage to a system for a prescribed length of time, measuring the leakage current through the insulation. This measurement is expressed as resistance and, when tested periodically, can be used to graph and evaluate the condition of a motor’s overall insulation over time. This critical information can indicate wear and damage patterns, allowing operators to stay a step ahead of maintenance needs and address issues before serious damage occurs.

A complex tester, the Megger needs to be set, connected, and operated very carefully to prevent equipment damage and operator injury caused by the high levels of voltage involved. Also, motors under testing must be disconnected and isolated for proper observation — a key aspect of a full motor winding analysis.

4. The Voltage Drop Test: Analyzing Resistance in High-Amperage Circuits

Of the many motor tests available, a voltage drop test is among the quickest, easiest, and potentially most valuable, allowing for easy evaluation of the quality and efficiency of your circuit’s operation. A voltage drop test can be readily performed with a basic load and a digital voltmeter (DVM). Once the load is applied, the DVM can measure the live connection for a voltage drop in the circuit under load.

Because electric current will arc in the path of least resistance, excess current will naturally flow to the DVM and create a reading. And, if the circuit was previously broken, the DVM can create a temporary flow to attempt to isolate the area of dropped power.

An indication of voltage drop is often an early warning sign that cleaning, maintenance, or routine repairs are needed.

5. The Core Loss Test: Ensuring Quality and Reliability

While every motor experiences some inherent energy loss, increased or abnormal power loss can be indicative of a bigger problem — physical damages, overheating, or ineffective winding or rewinding. In fact, core loss can account for some of the greatest energy waste in electric motors and even in entire manufacturing systems.

A core loss tester can indicate the difference between a motor’s input and output power, and these statistics can then be charted against acceptable levels and industry standards. While some loss is normal, a significant loss can reveal repairable problems before they become serious. It can also be a strong indicator of motors in need of replacement, helping to ensure that even a rewound motor is maintaining its ideal performance and efficiency.

Motor Testing and ANSI/EASA Standard AR100-2105

All of the above tests are done in accordance with ANSI/EASA standard AR100-2105, which outlines recommended practices for the repair — and therefore the testing — of rotating electrical apparatus. The 2015 edition of AR100 — which was introduced in 1988 and has been previously revised in 2001, 2006, and 2010 — includes more than 100 revisions, which aim to further improve motor quality, safety, and performance. The tests outlined above are just a small sampling of those offered by Renown Electric.

For companies looking to improve the quality, performance, and life of their motor, they should first be sure that the shop they’re partnering with conducts tests in accordance with AR100 guidelines; this illustrates a commitment to best practices and adherence with critical industry regulations.

Routine Maintenance Practices and Motor Testing with Renown Electric

Motor testing is a low-impact, high-value way to extend the life of your equipment. Regularly scheduled diagnostics and thorough troubleshooting at the first sign of a problem can lead to more efficient, timely repairs, more effective operations, and less frequent damage to the overall system.

The team at Renown Electric offers customer support 24 hours a day, seven days a week, working to keep your motor running at its prime. Maintenance programs and troubleshooting diagnostics are just one aspect of our capabilities; we’re been providing top-of-the-line repair services to a wide range of industries for over three decades.

Reach out to our experts today for help in extending the life of your motor!