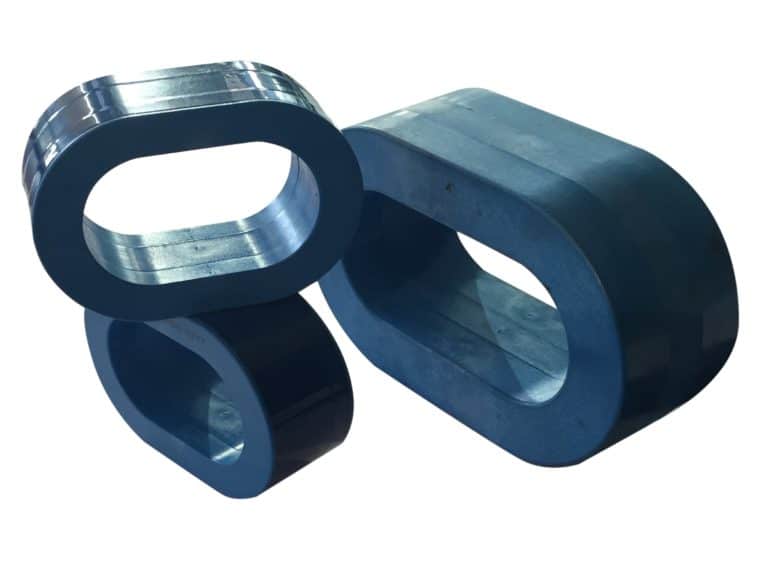

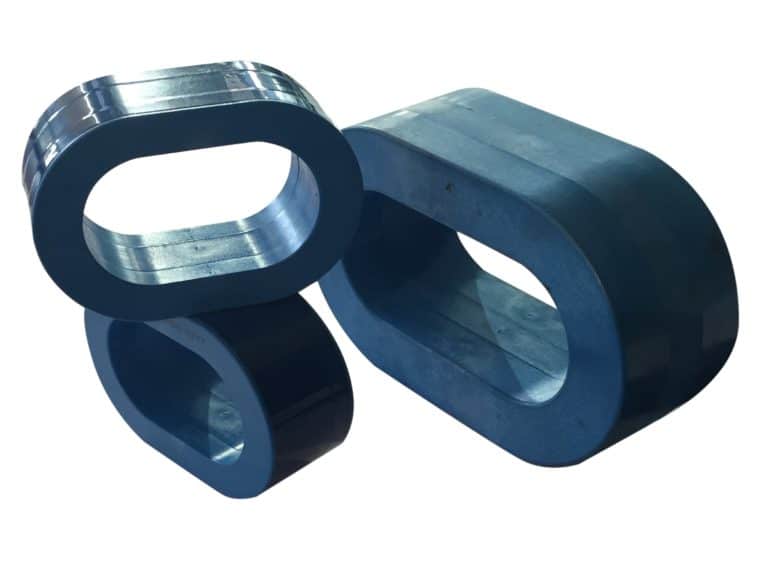

CoolBLUE Cores Reduce Motor Bearing Currents by Over 65%

Most modern electric motors run via a variable frequency drive (VFD) for AC motors and DC…

Get Resource

Most modern electric motors run via a variable frequency drive (VFD) for AC motors and DC…

Get Resource

A proper maintenance program can prevent most equipment failures. Implementing the right maintenance program is…

Get Resource

In the oil and gas industry, electric motors and generators are used for a wide…

Get Resource

On a smaller scale, hydroelectric power generates between 6-10% of all energy in the United…

Get Resource

Download our latest cost analysis Repair and maintenance costs represent the second-highest expenditures within the…

Get Resource

Correct alignment of components within a motor ensures proper operation and can boost its performance.…

Get Resource

Modern elevator motors, whether powered by a variable frequency drive (VFD) for AC motors or…

Get Resource

Machine wear caused by inadequate lubricant performance costs industries billions of dollars every year in…

Read More

Renown Electric has long been committed to providing quality proactive and preventative maintenance measures. After…

Read More

Oil analyses are performed on used engine oil to determine the specific properties and characteristics…

Read More

Facility equipment — especially industrial motors — naturally wear down throughout operation, sometimes to the…

Read More

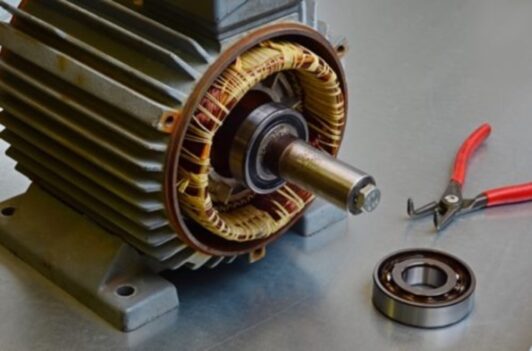

Renown Electric treats every motor project — big or small — with the same level…

Read MoreNo matter your industry or application, we’re here for you. Contact us to learn more about our extensive capabilities, and how we serve clients across industries to ensure their motors are operating at their best.