Today’s high-efficiency mines rely on effective hoisting and transportation systems to move people, goods, and equipment. Having the right hoists and safety equipment is essential for growing your operation while protecting your employees. Learn more about mining hoists, our upgrade and repair services, and Canadian regulations for surface hoist operations.

Mining Hoists Explained

Electric hoists raise and lower the conveyances in underground mines. Miners rely on them for daily operations: moving equipment, crushed ore, and people between the surface and the mining zone thousands of feet underground. In fact, mine hoists are often the only way to transport mining equipment and personnel to and from mining sites. Because human life depends on these systems, they need to provide consistent reliability with no risk of failure or miscalibration.

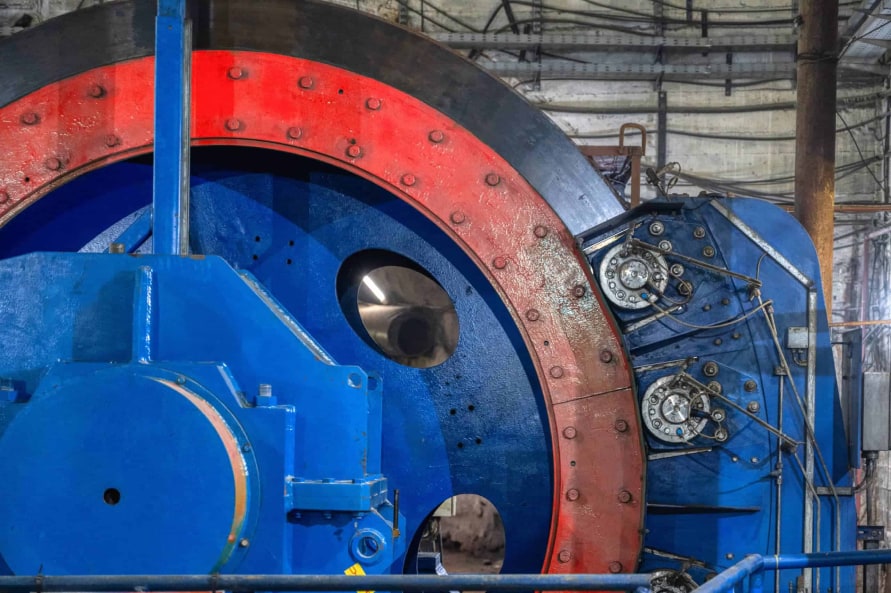

The electric components that control these hoists need to have the right power levels for these heavy loads and the right protections to ensure safe, reliable operation. Mining hoists commonly use electric motors powered by either AC motors with variable frequency drives or DC motors with solid-state converters. Drum hoists feature a sheave and headframe assembly, which are vital to the safe operation of underground mines.

At Renown Electric, we provide repair and troubleshooting services for AC and DC mining hoist motors and controls. Not only are our drive repairs tested for complete reliability, but we also offer controller trending and PMs to increase mine production and optimize cycle times.

Types of Electric Mine Hoists

There are many different types of mine hoists available for mining companies to select from, including:

- Blair hoists

- Escape hoists

- Friction hoists (Koepe hoists)

- Single drum hoists

- Double drum hoists

Each system includes digital controls, full automation, hydraulic brakes, motors, and drives. Powered with an electric or hydraulic drive, our team will work with your preferred partners to assist with assembly, factory or field testing, and commissioning.

Updates and Repairs for Mining Hoists

At Renown Electric, we specialize in servicing electric drive systems for critical applications such as underground mining. We design, manufacture, and thoroughly test hoist systems so our clients have a complete solution for their worksites. In addition to these services, we also provide:

Part Repair and Replacement

Mining companies around the world trust Renown Electric for:

- Replacing old or worn drives quickly to minimize unscheduled downtime

- Repairs for motors, generators, and drives

- Repairs for electronic components

Part Remanufacturing

Our team can rebuild or recover non-functional components for legacy systems and complex hoist equipment. Some of our most common remanufacturing projects are for:

- Bull gears and pinions

- Clutches

- Enclosed gearboxes

Mining Hoist Regulations in Canada

Mining environments can be extremely hazardous, so equipment needs to meet strict standards to ensure the safety of workers and the efficacy of the worksite. The Coal Mining Occupational Health and Safety Regulations establish these standards in Canada, dictating the minimum requirements for surface hoist systems, from the framing and installation requirements of the system to the safety and emergency systems that must accompany each unit. The full list of regulations can be found here.

At Renown Electric, we take care to ensure all of our products and services meet or exceed these safety and performance requirements so you can operate your site with peace of mind.

Expert Services From Renown Electric

A reliable and well-maintained mining hoist can make all the difference for the safe and efficient performance of your mining operations. Renown Electric’s team is here to help with your mining hoist repair and maintenance needs for safe movement in mines, with levels reaching hundreds to thousands of feet below the surface.Contact us today to learn more about our mining hoist repair services.