Prevent Downtime with Renown’s Coast-to-Coast Field Services

Comments Off on Prevent Downtime with Renown’s Coast-to-Coast Field ServicesWhen an electric motor can’t perform to capacity, your company suffers—equipment failure leads to reduced productivity and loss of revenue.

If your equipment can be brought to a repair shop, a trained technician can help. Unfortunately, many customers find themselves at the mercy of their local technicians’ schedules; in these instances, it’s best to choose a company that’s available when you need them most.

At Renown Electric, our coast-to-coast, around-the-clock service keeps your business up and running at all times. Our team helps diverse companies reduce their down time and get machines in working order quickly.

Renown provides a variety of field services for your motors, including:

• Surveys – Renown conducts motor brush surveys to identify and correct motor problems before they become more severe. We also offer modernization surveys to ascertain the most ideal equipment choice for your application.

• On-Site Machining – When equipment is starting to wear but is too large or cumbersome to transport, we bring our machining capabilities on-site. We have the capabilities to mill, weld, drill, thread, ream, and bore, helping to restore your equipment to run like new.

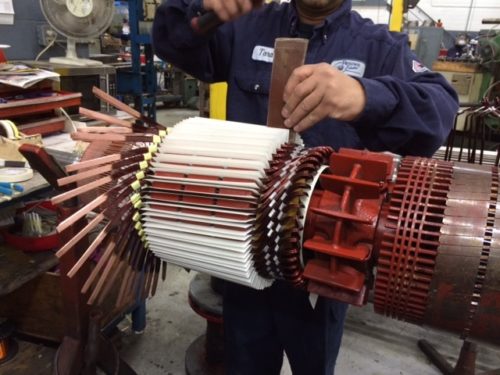

• In-Field Rewinding – Rewinding is essential as insulation breaks down over time and under various day to day stresses. Our services include an evaluation of both AC and DC components, the manufacturing and installation of new components such as coils. This new equipment is then tested and verified to the letter of today’s standards.

• Turning and Undercutting – One method to alleviate excessive wear on machinery (while promoting proper electrical current transfer) is with Renown’s turning and undercutting capabilities—which can eliminate vibration, arcs, and burring as well.

Remember that these services are available 24 hours a day, 7 days a week—either at your facility’s location or in our advanced 25,000 square foot repair facility. If your equipment has gone down, is lacking in service, or if you’d like to explore ways of expanding and modernizing your current services please contact Renown Electric today.