Deep Pit Access & Elevator Guarding

Elevators have large moving parts that present a potential danger to operators and workers. But elevator room machine guards from Renown provide reliable protection that makes elevator rooms safer for day-to-day operations, inspections, and repairs. Each of our car-top, global, and component-guarding elevator ladder solutions meets or exceeds applicable regulations and safety guidelines, including those set by OSHA and MOL. Our systems include a patent-pending retractable ladder that exceeds regulatory or safety requirements, allows for efficient movement, and provides ongoing peace of mind. Learn more about our elevator pit ladders and what makes them ideal for use across large-scale commercial, municipal, and industrial applications.

Our Elevator Pit Ladder Features

Every aspect of our elevator pit ladders is built to increase safety. This starts with a unique design that allows for three points of contact at each step. The ladder can also be where the user needs it on the landing through our rope and pulley deployment and retraction system. This special design means users never have to even consider making a leap of faith. It takes less than nine pounds of pressure to get the ladder in place and ready to use.

Additional features of the elevator pit ladders from Renown include:

- Wall-mounting capabilities: Each ladder allows for wall-mounting in simplex installations or mounting along trimmer beams for duplex, triplex, or quad installations.

- Integrated wheel-brake assembly: Operators can wheel the ladder into position. But the brake automatically engages to stop wheel motion to stop any potential roll-out when there’s weight on the ladder.

- Simple setup: Users can be in position at the entry or exit point in two minutes or less. This saves significant amounts of time with every trip compared to traditional fall-arrest systems (which can take hours to make operational).

- Options for different environments: The elevator pit ladder can be used in spaces of any depth from four feet to over 30 feet deep. It also works in hoistways of any profile.

- Automatic elevator restriction: The ladder breaks the elevator safety string with a normally-open limit switch. This guarantees that the elevator cannot move either up or down while someone is using the ladder. This safety feature eliminates the risk of elevator movement throughout ladder deployment.

All of these safety features comply with or exceed applicable regulations and ensure operators are safe during use.

Industry Applications

Deep pit access elevator ladders are designed to perform in virtually any environment. Four key applications of our ladders include the following:

Larger Hotel Industry

Smaller elevators often don’t have elevator rooms because they rely on hydraulic elevators or electric machine-roomless (MRL) elevators. But the high-speed elevators found in large hotels require deep pits with safe, efficient, and fast access processes. With a safety ladder from Renown Electric, operators can enter and exit within two minutes, allowing for faster maintenance checks, repairs, and operational tasks that reduce the impact on elevator availability.

Commercial Office Buildings

Commercial office buildings often have large banks of elevators to ensure the efficient movement of large groups of people and objects at peak travel times. With a pit ladder, operational teams can perform tasks without shutting down all of the elevators in the bank. In fact, the ladders can be mounted to multiple beams or mount points so operators can have flexible access to any part of the elevator pit without significantly slowing down or interrupting traffic.

Residential Buildings

Large residential buildings such as high-rises face many of the same traffic concerns as offices. There are large numbers of people, often with extremely busy peak usage times. Maintenance teams need safe, efficient solutions so they can manage entry and egress with minimal downtime. High-rise and express elevators are high-speed systems, which need deep pit access. The right elevator pit ladder makes access to any point in the pit faster.

School Buildings

Multi-story school buildings need elevators to guarantee accessibility throughout the campus. Not only do fast-moving elevators in multi-story buildings require deep pits, but occupants are likely to drop items like phones, tablets, and keys into the pit below. With our pit ladder solution, operators can quickly gain access, perform necessary tasks, and exit without compromising on safety.

Elevator Pit Ladders by Renown Electric

The right elevator pit ladder offers both optimal safety and fast functionality. Our pit ladder solutions exceed the requirements of safety regulations, and they make fast access possible in virtually any elevator pit. Contact us today to learn more about our elevator ladders and how to find the right fit.

Renown Electric’s elevator guards and machine room guarding sets protect workers from injury and are designed to prevent accidents in the workplace.

Our elevator room machine guards protect workers from being injured by large moving parts. Renown’s car-top, global and component guarding program meets or exceeds OSHA and MOL requirements for elevator machine rooms.

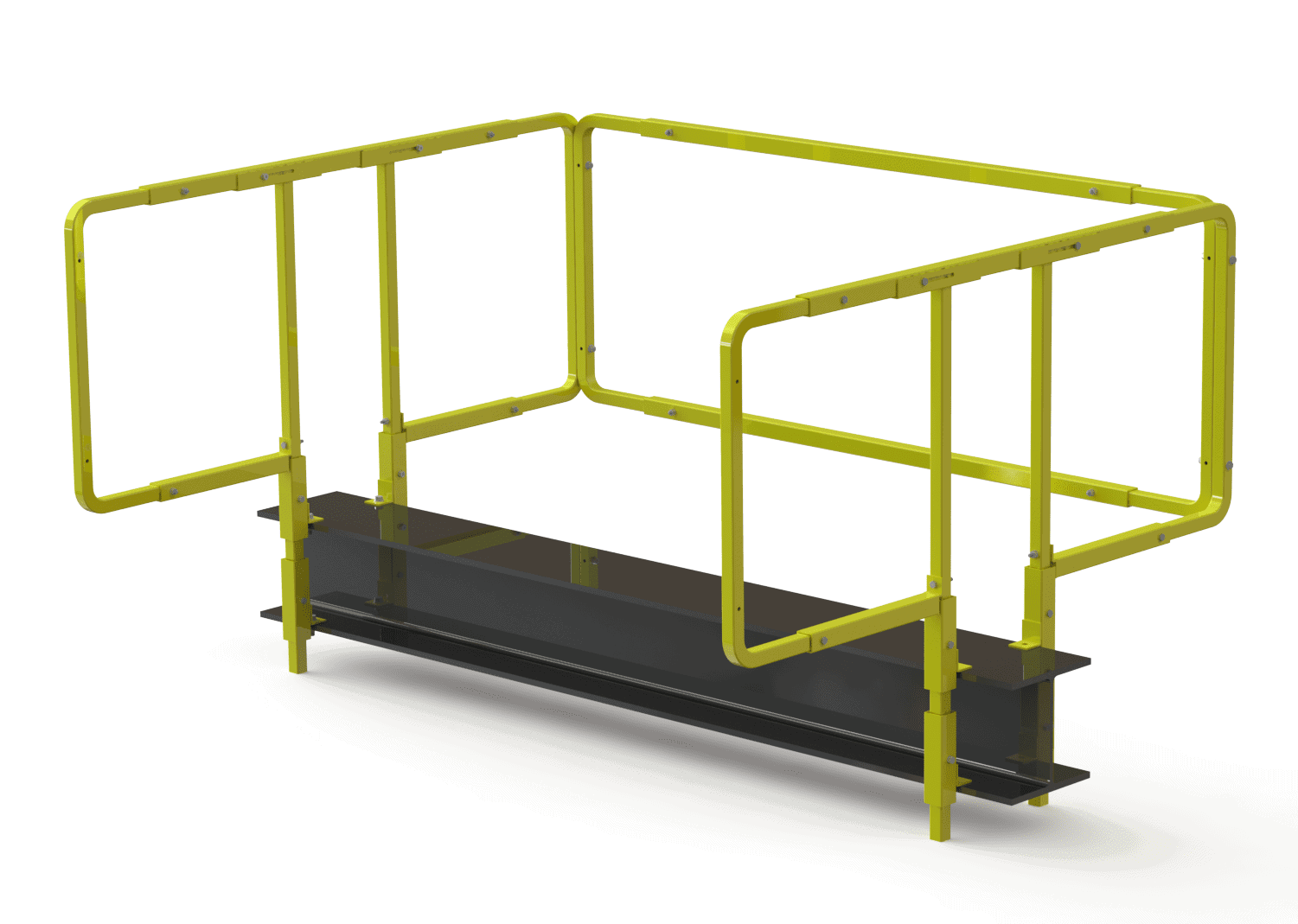

Car-Top Guarding

Renown Electric’s car-top elevator guard system boasts a host of advantages, including quick and simple installation and easy adjustments for the most common car sizes. We stock two main sizes and are ready to ship at any time:

- Small – 0004: Back adjusts from 51 – 68 inches. Side adjusts from 41 – 57 inches. Head beam sizes from 8 – 13 inches. Total unit weight is 105 lbs.

- Large – 0006: Back adjusts from 55 – 90 inches. Side adjusts from 53 – 70 inches. Head beam sizes from 8 – 14 inches. Total unit weight is 135 lbs.

Custom sizes are available upon request. All units include kick plates, hardware, installation instructions and stamped engineer drawing. Units are designed in accordance with TSSA B44-07 8.7.14.

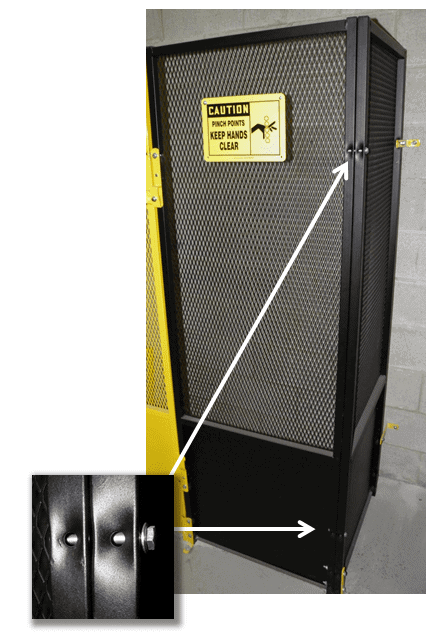

Global Machine Guarding

Our modular global guarding sets are fabricated specifically to precisely fit into the machine room and around the equipment. Following a machine room survey, Renown designs and manufactures a custom hingeless system that installs easily and creates a safe workplace.

- Guarding Design Standards: The enclosure is installed by joining panels together with bolts, minimizing the need for additional posts. Yellow powder-coated access panels lock at two points and lift out for easy access to the enclosed

car area. In addition to being OSHA compliant, this system meets elevator industry best practice standards. Machine safeguarding requirements as per the Occupational Health and Safety Act, CSA Z432-04 Standards for Safeguarding of Machinery, Elevator Machine Room Equipment Guarding (a best practices guideline produced by the industry stakeholders).

In addition to being OSHA compliant, this system meets elevator industry best practice standards. Machine safeguarding requirements as per the Occupational Health and Safety Act, CSA Z432-04 Standards for Safeguarding of Machinery, Elevator Machine Room Equipment Guarding (a best practices guideline produced by the industry stakeholders).

- Maintenance Access: Removable access panels locked at two points are provided for easy car access by simply lifting them out. A hingeless system design eliminates pinch-point at the door.

- Simple Installation: Our global guarding system for elevator machine rooms offers complete interchangeability of all panels.The modular design, consisting of panels with the ability to be joined together, eliminates the use of posts and ensures simple, hassle-free installation. The panels are connected together by two fasteners and the doors are placed in holder brackets, which are secured with a bolted latch. The panels are secured to walls and the floor through the use of drop-in anchor bolts.

- Included with Guarding Sets: Machine room survey, installation layout, safety review checklist, option safety compliance review report, safety signage.

Component Guarding

Renown Electric Motors & Repair Inc. is a proud distributor of the Flavesco component guarding system. This innovative elevator machine guarding solution is modular, lightweight, and fits within the machine footprint. Access panels are hinged or removable and hi-flow vented panels protect openings on motors or generators.

Renown Electric Motors & Repair Inc. is a proud distributor of the Flavesco component guarding system. This innovative elevator machine guarding solution is modular, lightweight, and fits within the machine footprint. Access panels are hinged or removable and hi-flow vented panels protect openings on motors or generators.

For more information, we encourage you to view Flavesco’s Elevator Machine Guarding brochure.

Both of our machine guarding systems meet the challenges of the elevator room and are engineered for maximum safety and risk mitigation. To learn more about the total turnkey guarding package, please contact Renown today.