5 Common Elevator Problems and Prevention Tactics

2 CommentsFrom old operating systems to worn sheaves, there are a number of reasons why an elevator may be malfunctioning — and our team at Renown Electric is always available to help.

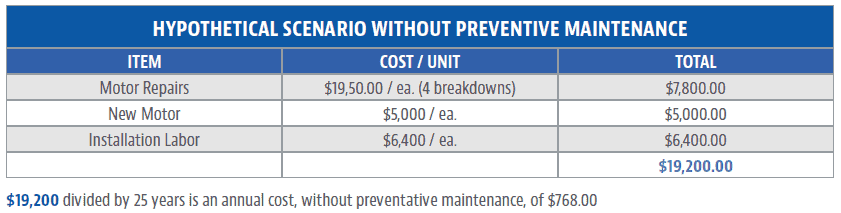

Many equipment failures can be prevented with proper inspection and preventative maintenance. Regular maintenance doesn’t just increase productivity by avoiding downtime — it’s also been shown to decrease energy consumption by 15%.

Long wait times and frequent breakdowns are inconvenient and a sign of wear. Overheating, high energy use, and low power factor may not be obvious problems, but they incur hidden costs. Implementing simple elevator motor maintenance practices can help decrease expenses and downtime.

Below, we examined some of the most common elevator problems and provided solutions to preventing elevator downtime:

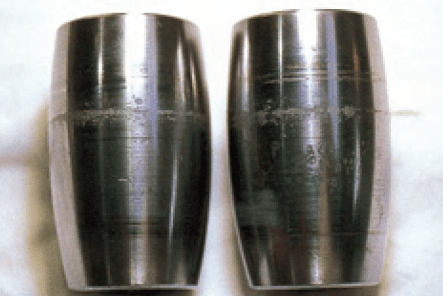

1. Problem: Worn Sheaves

✓ Solution: Sheave regrooving

Worn sheaves place extra wear on ropes, which in turn increases the level of wear on sheaves. This creates a cycle of destruction for both key components.

Sheaves can be regrooved or replaced to prevent premature hoist rope failure, so be sure to check groove profiles to verify the fit between the ropes and the sheave. Simple tools are available with magnetic standards and a straight edge to visually check if the grooves on the sheave a wearing evenly.

2. Problem: Power failure

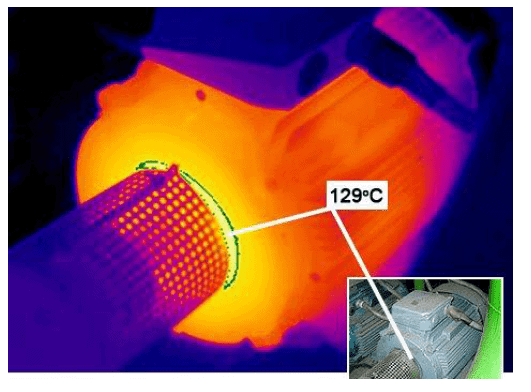

✓ Solution: Infrared inspection

Elevators demand a great deal of power from commercial building utility systems, so updates to the system’s voltage can affect motor operations or potentially even damage the elevator system. Elevators with any history of motor failures or operation issues should undergo a power quality survey.

Infrared thermography measures drastic temperature changes and can identify possible trouble spots before they cause costly system failures. Common faults such as over/under voltage can be seen easily with power quality surveys and fuses that are running hot can be quickly seen with infrared imaging before a motor loses a phase.

3. Problem: Contamination

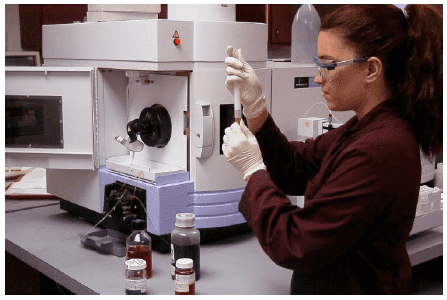

✓ Solution: Oil & lubrication analysis

When wear occurs, small metal particles are released in the oil and can interfere with the proper functioning of an elevator system. Similarly, improper lubrication or worn seals can cause contamination. Conduct an oil analysis to check the oil for various properties that may indicate contamination or wear inside of a motor.

A high presence of bronze in the gear case oil can indicate premature wear on the crown gear of a geared elevator or high concentration of aluminum in your hydraulic tank may indicate pump housing wear in a hydraulic elevator.

4. Problem: Noisy bearings or bearing malfunction

✓ Solution: Inductive absorbers

Bearing malfunction causes more than half of all motor failures. Noisy bearings are often attributed to vibrations within the motor. While variable frequency drives are helpful for decreasing your motor’s energy use, they introduce common mode current — a damaging byproduct that can increase these vibrations to dangerous levels through premature bearing wear caused by stray current.

To address this challenge, consider using an inductive absorber, such as CoolBLUE, to absorb the currents and protect your system from potential breakdowns. Additionally, ensure that all grounds are secured and connected to minimize troubles caused by electrical noise on the ground that may trip out systems or cause false counts in the system.

5. Problem: Misaligned motor drive

✓ Solution: Motor alignment

When an electric motor is coupled to another piece of equipment, shaft alignment is critical. Without correct alignment, the motor bearings begin to wear. Shaft misalignment can be detected using advanced laser measuring equipment or by simply employing a straightedge and string.

When an electric motor is coupled to another piece of equipment, shaft alignment is critical. Without correct alignment, the motor bearings begin to wear. Shaft misalignment can be detected using advanced laser measuring equipment or by simply employing a straightedge and string.

Alternatively, consider purchasing geared machines that employ flange mounted motors that do not require alignment if the machine is disassembled.

Other Solutions

preventative maintenance and on-site elevator repair services to customers across a broad range of industries.To learn how to avoid the causes of elevator malfunction altogether, check out our