Blog

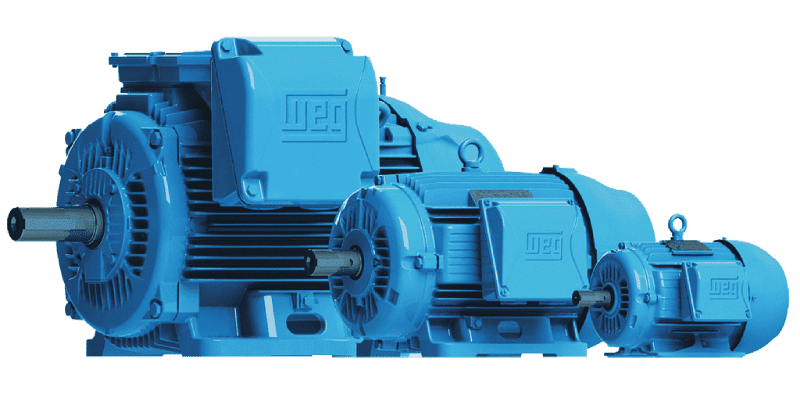

Knowing the difference between NEMA and non-NEMA motors will help you and your product team choose the right motors for your designs, both in terms of product performance and in terms of the efficacy of design and manufacturing in an increasingly global market. At Renown Electric, we specialize in large non-NEMA motors, as well as NEMA and IEC motors, that are designed to provide a high level of performance. Learn more about NEMA electric motor standards and NEMA motor class designations.

The NEMA standards cover a wide range of electric motor frame sizes used in North America. However, there are some electric motors that are larger than the largest NEMA frame sizes. These motors are typically used in heavy industrial applications, and their frame sizes are often designated by different standards.

One common standard for larger electric motor frame sizes is the IEEE (Institute of Electrical and Electronics Engineers) standard. The IEEE standard defines frame sizes for large AC and DC motors used in industrial applications. These frame sizes range from 315 to 1000, with corresponding shaft heights ranging from 400 mm to 1600 mm.

Another standard for large electric motor frame sizes is the IEC (International Electrotechnical Commission) standard. The IEC standard defines frame sizes for AC motors used in Europe and other parts of the world. These frame sizes range from 315 to 1000, with corresponding shaft heights ranging from 400 mm to 1600 mm.

It’s worth noting that electric motors larger than the NEMA standards are often custom-built to meet the specific needs of the application they will be used in. These motors may have unique frame sizes, configurations, and performance characteristics that are tailored to the requirements of the application.

What Are NEMA Standards?

NEMA standards are the North American equivalent of IEC electric motor standards, and they primarily focus on the type of enclosure electrical components have (though NEMA standards encompass far more than this). Manufacturers can choose to design and produce components that comply with NEMA standards, but this is a voluntary distinction for electrical component manufacturers.

Electrical enclosures with a NEMA rating are assessed as meeting certain standards related to protection from corrosion, dust, and chemical damage. These standards are updated every five years and communicate to potential purchasers the level of durability that electrical enclosures have in certain environmental conditions. Non-NEMA motors and electrical enclosures can be just as safe as — or even safer — than NEMA products based on the regulations and quality standards of the specific manufacturer.

NEMA Design Classes

NEMA standards establish four distinct design classes. Motors that fall within each design class have different characteristics and are manufactured to have different levels of durability in their operational environments. The four NEMA design classes are:

NEMA Class A

Electric motors within NEMA Classes A, B, and C each have a maximum 5% slip standard. NEMA Class A motors must meet that standard with a medium or high starting current. They must also have a normal breakdown torque, or the maximum torque at a rated voltage and frequency level without decreasing in speed, and locked rotor torque, the torque the motor develops from a zero-speed start. NEMA Class A motors are trusted in a wide variety of commercial, industrial, and building applications, such as in fans and pump systems.

NEMA Class B

NEMA Class B motors must also have a normal breakdown torque, just like Class A motors. However, they need to have a low starting current and be able to accommodate normal starting torque levels. They also must be able to provide or withstand a high locked rotor torque. This distinction is ideal for motors that will power elements through HVAC systems.

NEMA Class C

NEMA Class C motors share many of the requirements of NEMA Class B products. However, they’re built for applications with a high starting torque and high level of inertia, such as large conveyor systems and heavy-duty systems.

NEMA Class D

NEMA Class D motors are built for high-inertia applications, such as oversized equipment including cranes and hoists found in construction or mining settings. These motors have a low starting current but a high locked rotor torque. They also have a maximum slip range of 5 to 13%.

NEMA Frame Sizes

Ranging from 42 to 449, NEMA frame sizes provide a standard by which all manufacturers can provide the same shaft, shaft height, length, etc. so that designers of equipment know in advance the dimensions a given motor based on HP and RPM.

NEMA (National Electrical Manufacturers Association) standards are a set of guidelines that establish standardization for various electrical equipment, including electric motor frame sizes. The NEMA standard for electric motor frame sizes defines the physical dimensions, mounting, and other characteristics of electric motor frames used in North America.

The NEMA standard for electric motor frame sizes covers a wide range of motor sizes, from fractional horsepower motors to large motors used in industrial applications. The standard defines specific frame sizes, which are designated by a number that indicates the overall size of the frame. For example, a NEMA frame size 56 is a common size for fractional horsepower motors used in appliances and power tools.

The NEMA standard also defines the mounting dimensions and other physical characteristics of the motor frame. This ensures that motors from different manufacturers can be easily interchanged and that the motor will fit properly in the equipment it is being used in. In addition to the frame size, the standard defines mounting options such as foot mounting or flange mounting, and specifies the shaft diameter and length.

Overall, the NEMA standards for electric motor frame sizes help to ensure that electric motors are compatible with the equipment they are being used in, and that they meet certain quality and performance standards.

Find NEMA Motors With Renown Electric

Renown Electric has been providing high-quality motors and motor repair services for over 35 years. Contact us today to learn more about sourcing the right electric motors for your next project.

Comments are closed