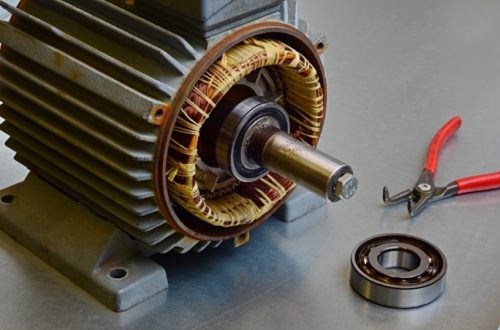

What’s that Noise My Motor Bearing is Making?

Comments Off on What’s that Noise My Motor Bearing is Making?In the course of our work, our team at Renown Electric Motors & Repair Inc. comes across a lot of motor drive and motor bearing issues.

Noise coming from the motor drive or bearing is a particularly common complaint. Working with our partner NTN Corporation, a Japanese bearing manufacturer with global reach, we compiled a few common causes of noise and vibrations in bearings and drives — and how to fix them.

What noise is my motor bearing making?

A motor bearing may make any number of noises, not all of which are indicative of a serious issue. Tinkling or rustling sounds, for example, are generally caused by dust or dirt and can be resolved with a decent cleaning. Others, however, can be more problematic.

Buzz or Roar

If your bearing is making a vibratory sound ranging from a light buzz to a considerable roar that increases in volume and pitch as speed changes, this is problematic.

This issue can be caused by any one of a number of factors, including resonation, a poorly shaped shaft, deformed bearing, brinelling, or vibrating parts. Note that in very large bearings, a minor buzzing is normal.

Screech or Howl

A screeching or howling sound, particularly on cylindrical roller bearings, that changes with speed is an indication of radial clearance that is too large.

(Note that if the sound is metallic and fades temporarily after being greased, the lubrication you are using is of a poor quality.)

Crunch

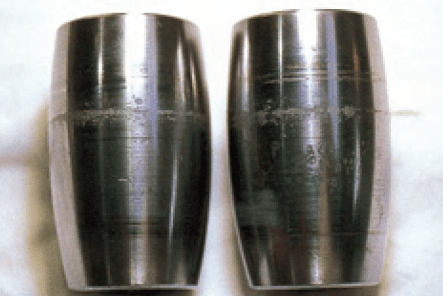

A crunching sound, especially one that can be felt when the bearing is moved by hand, could be caused by a deformed bearing or bad dust contamination. More seriously, it could mean that balls, rollers, or raceway surfaces are being scored.

Chatter

A chatter that is audible not only at high speeds but at low ones as well can mean that the rollers on a full-roller bearing are bumping into each other.

Find more causes of noise and vibration in NTN’s Motor Bearing Care & Maintenance Guide.

Why is my motor vibrating?

What do each of these sounds have in common? They can be traced back to vibrations in the motor. The degree of the damage caused by these sounds’ sources depends on both the amplitude and frequency of the vibrations causing them.

Slight motor vibration is normal. The presence of a variable frequency drive (VFD), while helpful for decreasing energy use, introduces electrical noise in the form of Common Mode Current. Common Mode Current can increase vibrations to dangerous levels that can cause audible noise issues and, more worryingly, badly damage your motor bearings.

The Ultimate Solution

CoolBLUE inductive absorbers, also called common mode chokes, are inductors that have been specially designed to reduce common mode current — they absorb the electrical noise, thus “choking” the current.

Proper installation of CoolBLUE inductive absorbers and NaLA differential mode line absorbers, both manufactured by Renown partner MH&W International, can decrease VFD-caused Common Mode Current drastically, as much as 70% or more. By reducing this noise and the vibration it causes, you will maximize the longevity and reliability of your equipment while minimizing maintenance cost and unscheduled downtime.

Learn more about Renown’s CoolBLUE Inductive Absorbers or see how they work in our motor bearing current case study.